- jw@steel-jw.com

- join. win

Tel :

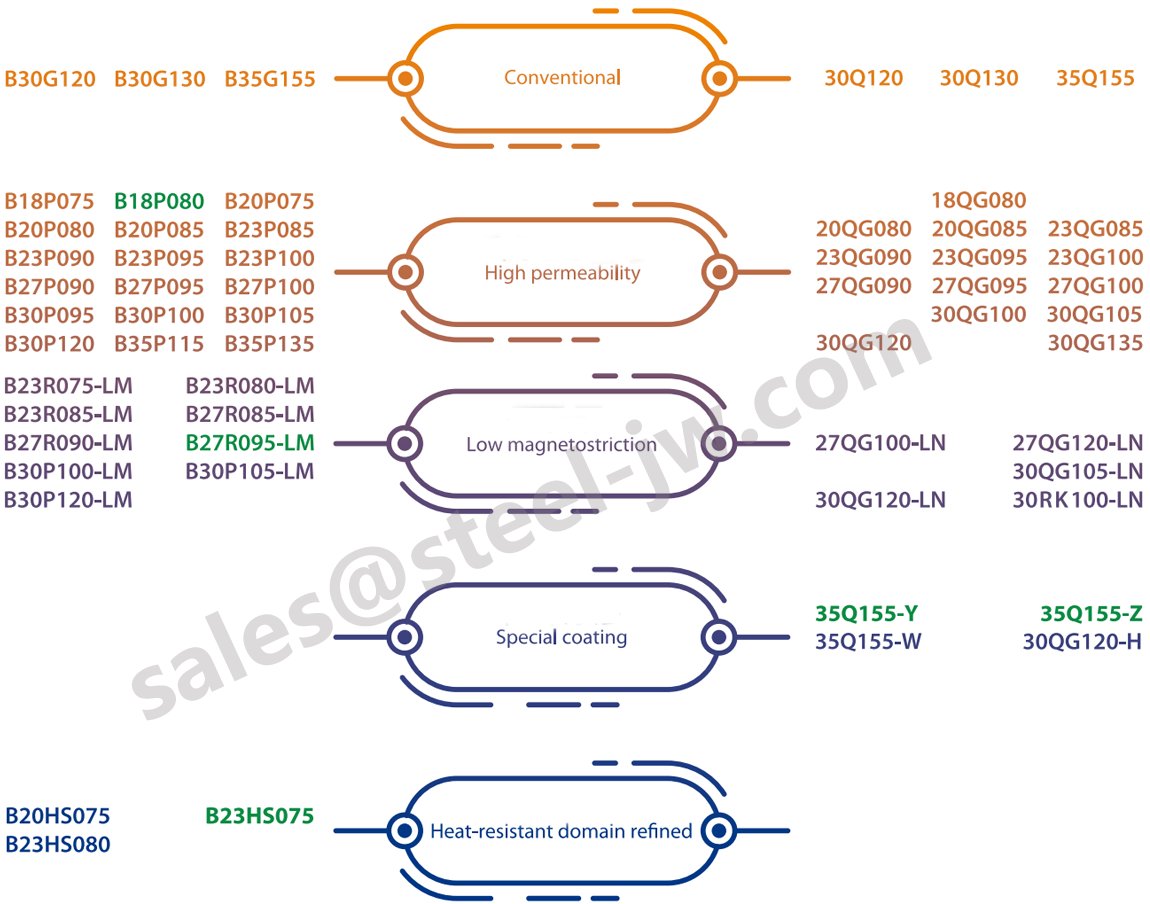

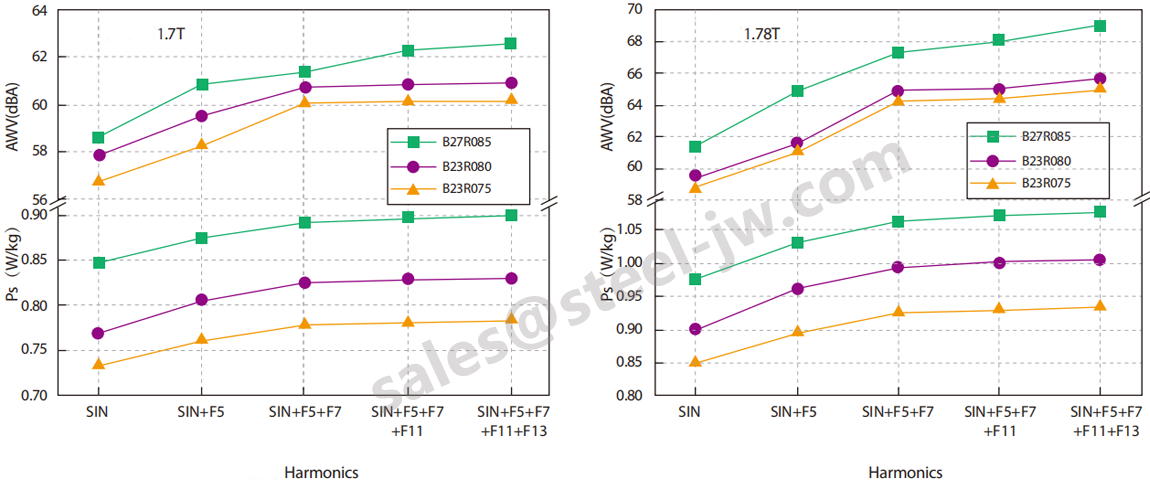

Note: The products in green font are the world's premiere products.

"- W" stands for no - glass - film products; "- Y" stands for C6 coating series products; "- Z" stands for self-adhesive coating series products;

"- H" stands for chromate free coating series products.

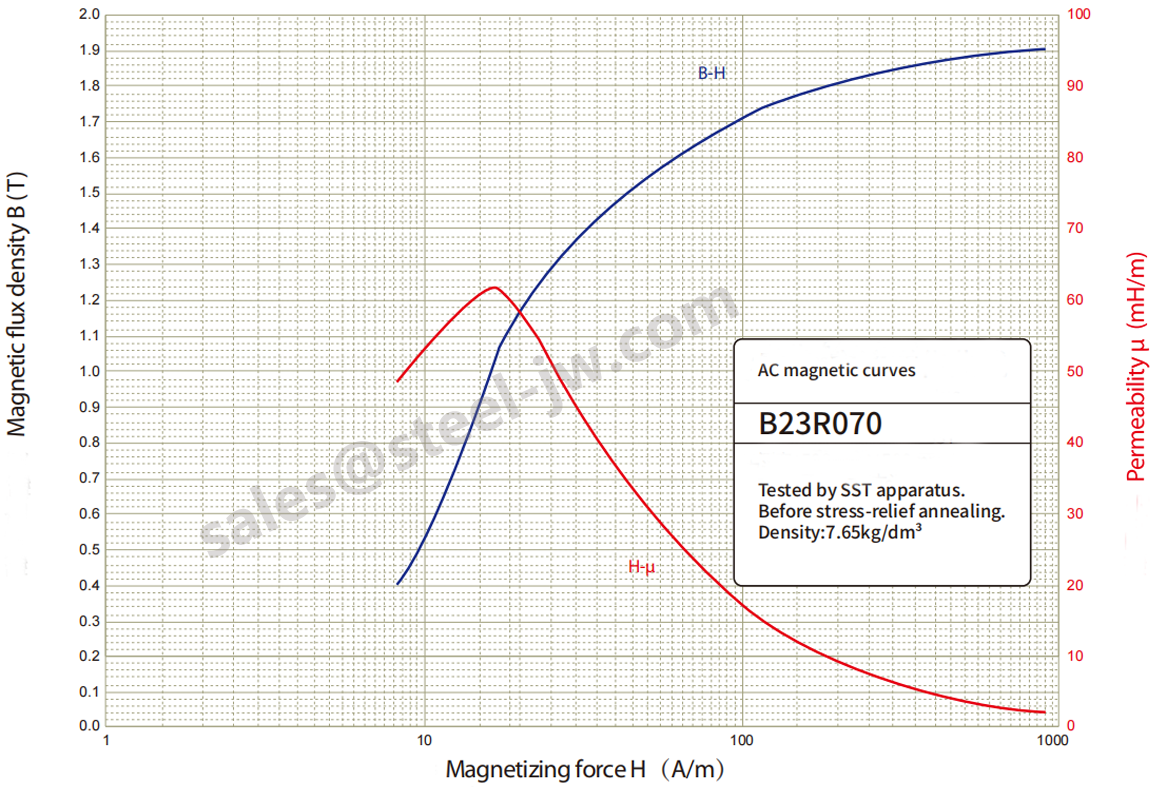

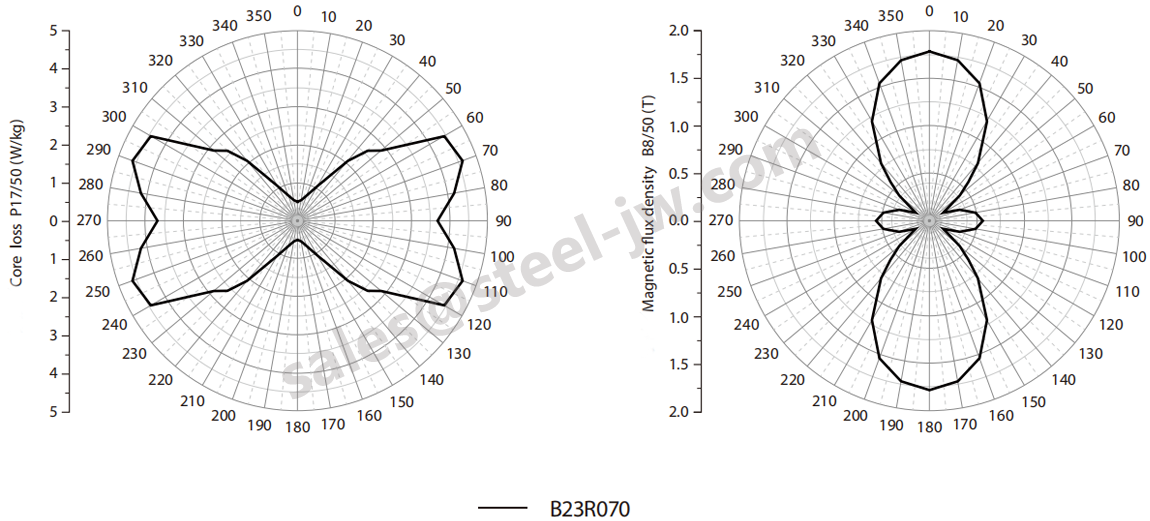

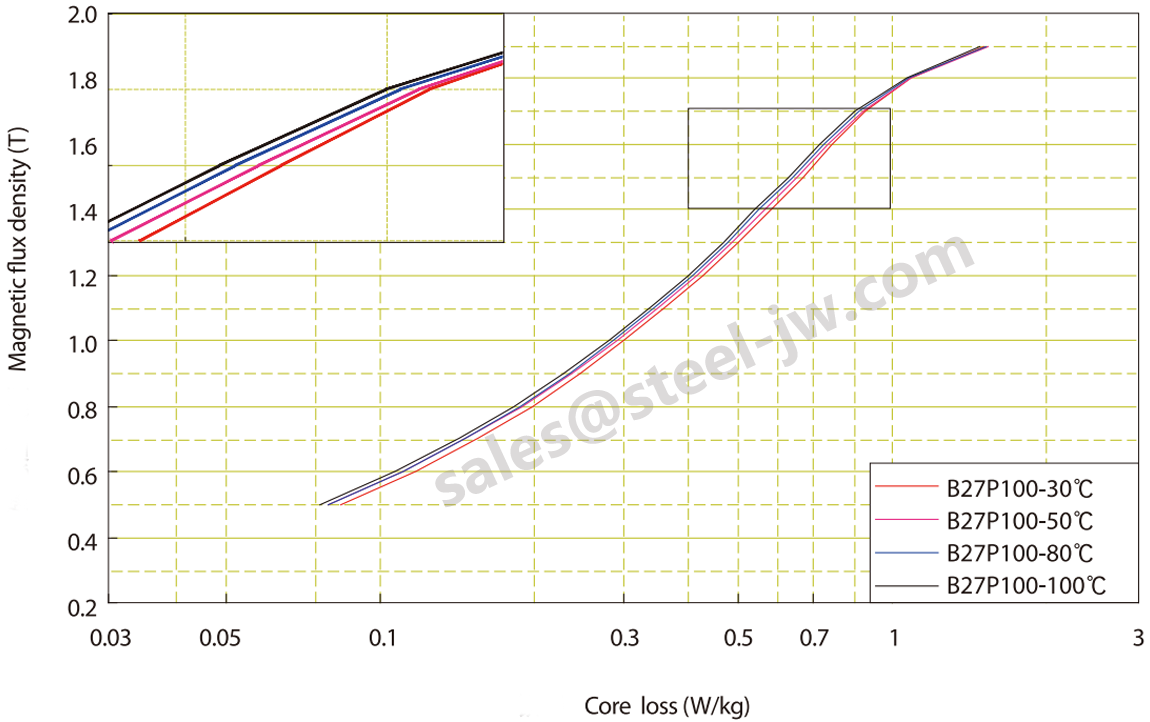

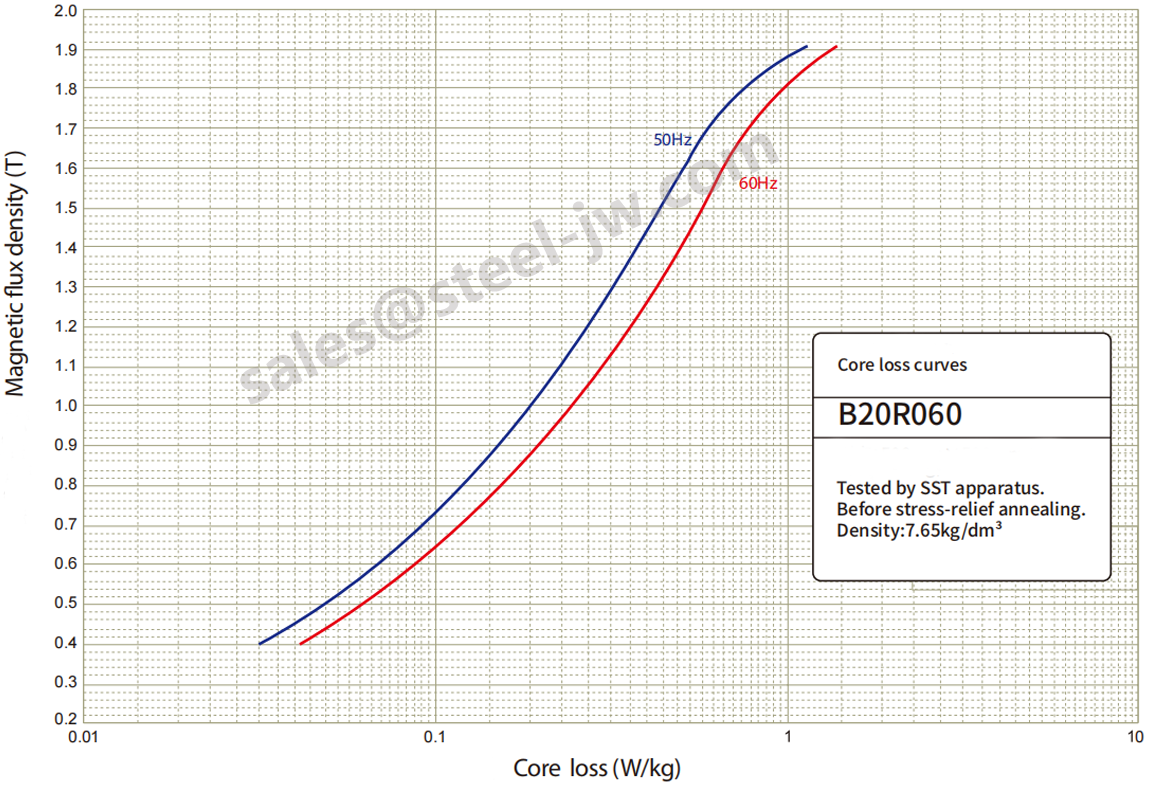

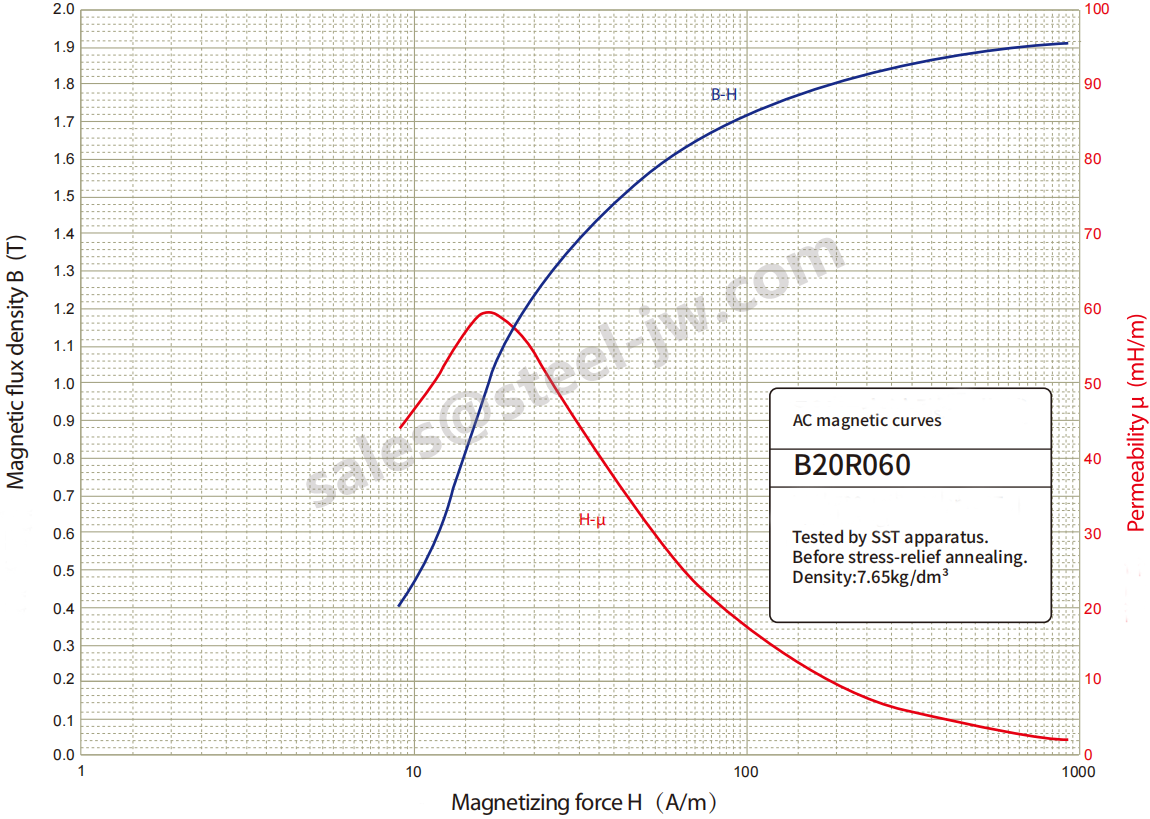

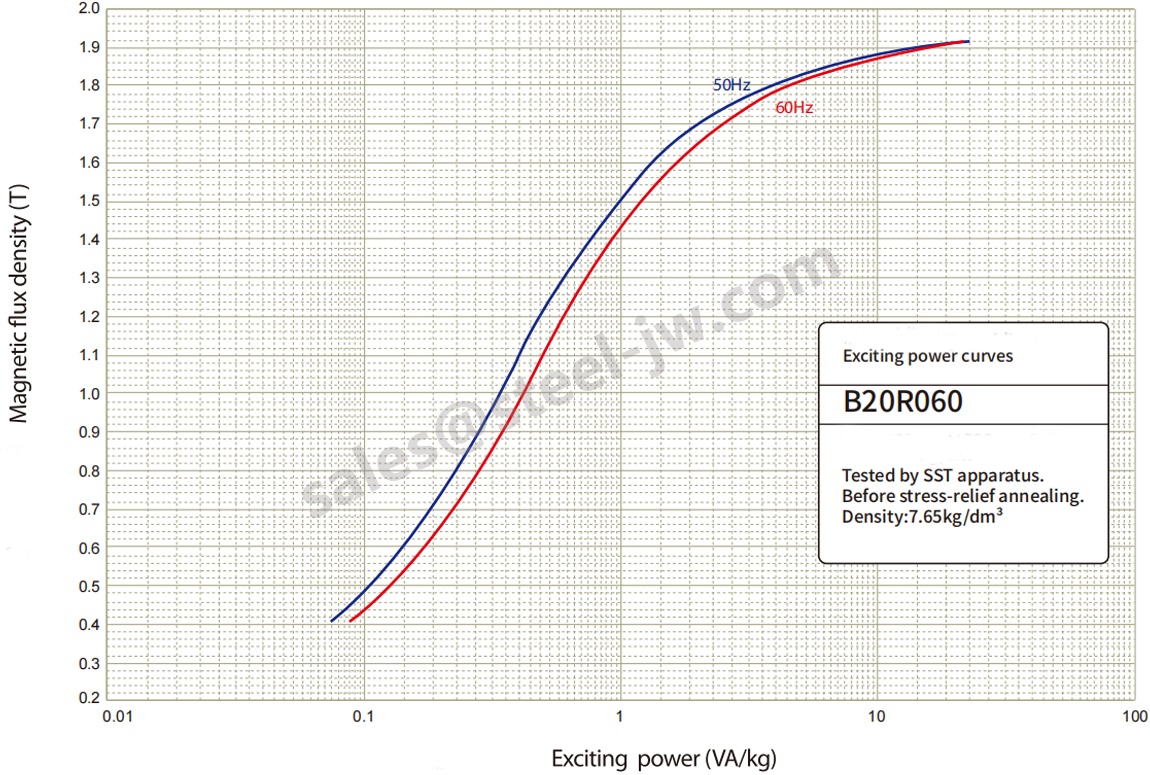

Continuously updates and improves properties database of products for transformer use, supporting customers with a range of full set of data from mechanical properties and basic magnetic properties to the properties under special working conditions. According to the diversed requirements, Baosteel can provide customers with performance data, the original curves, and other forms of data.

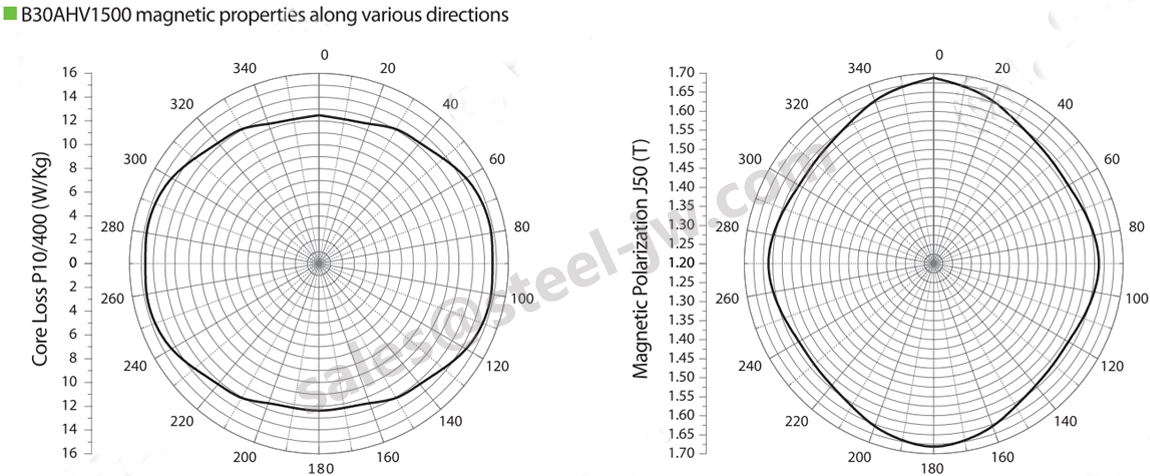

Basic magnetic properties |

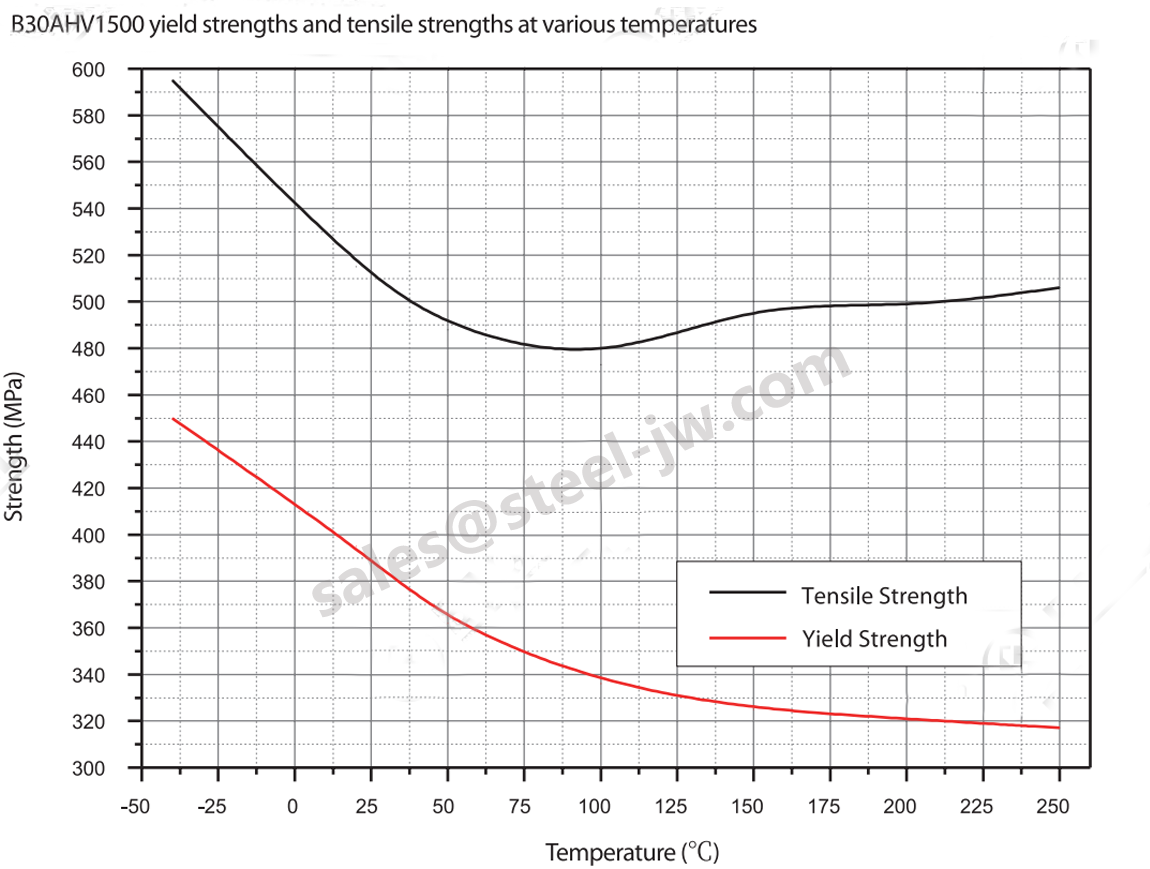

Typical mechanical properties |

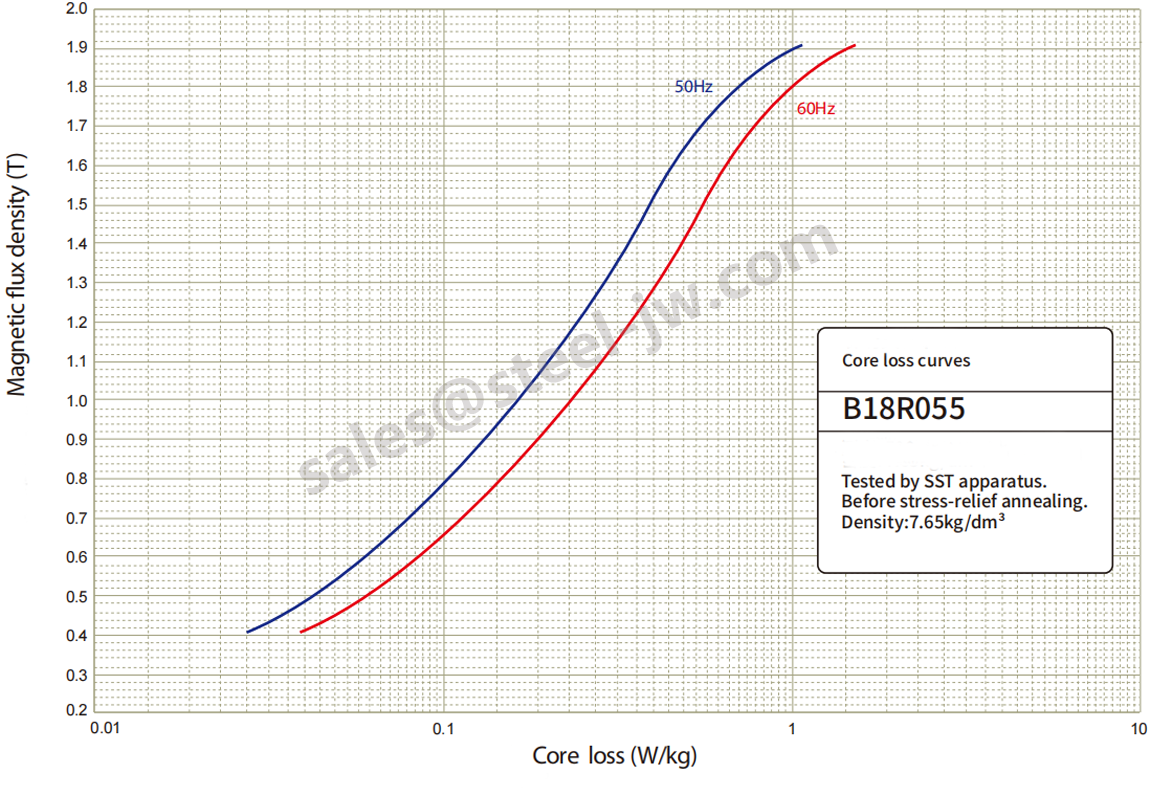

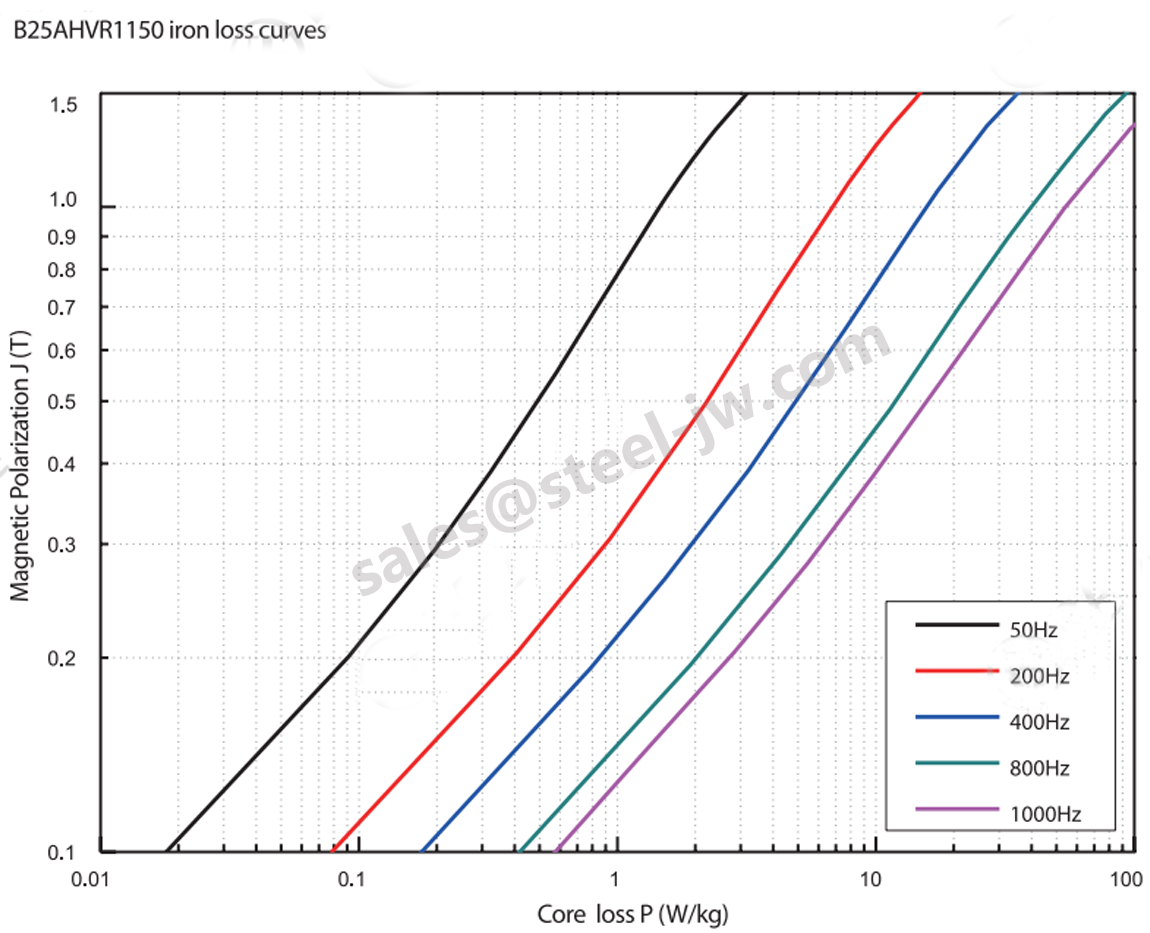

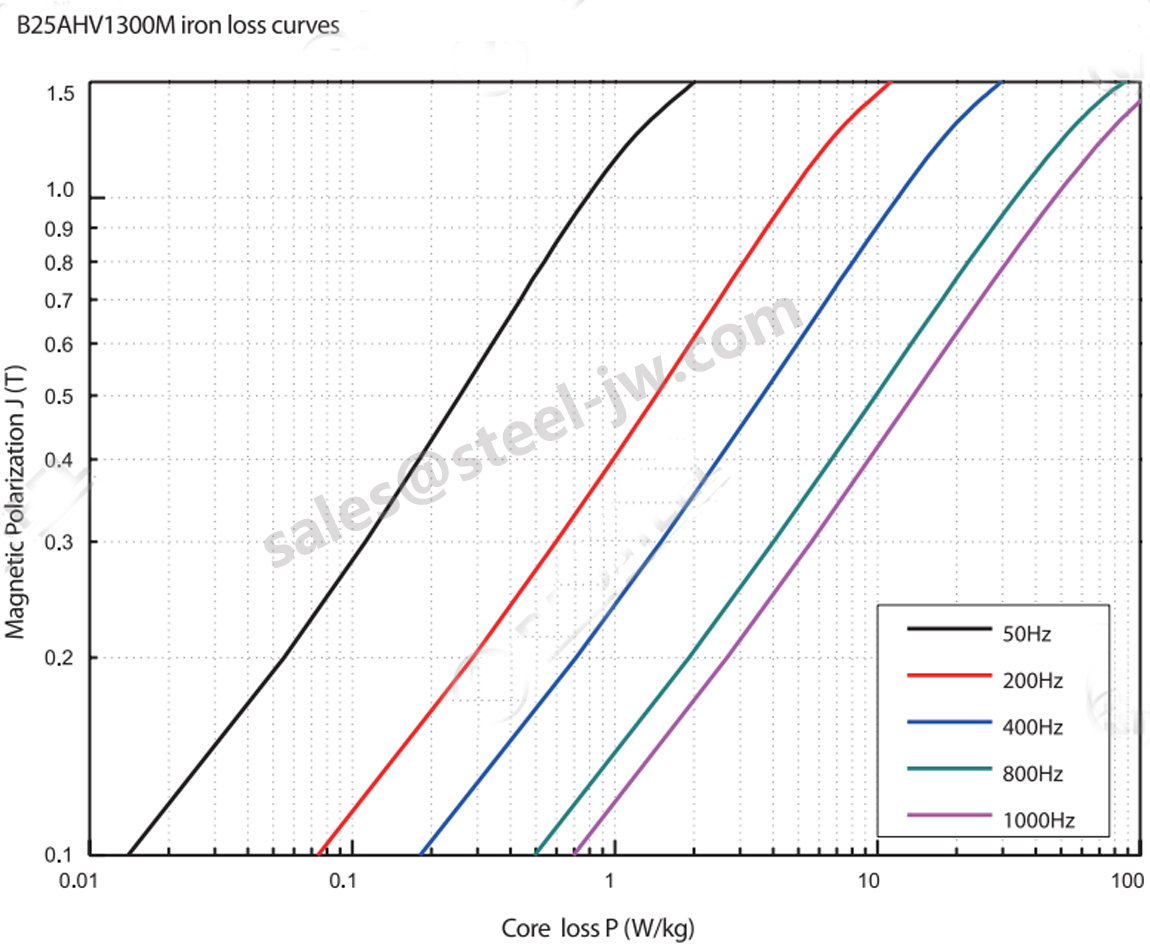

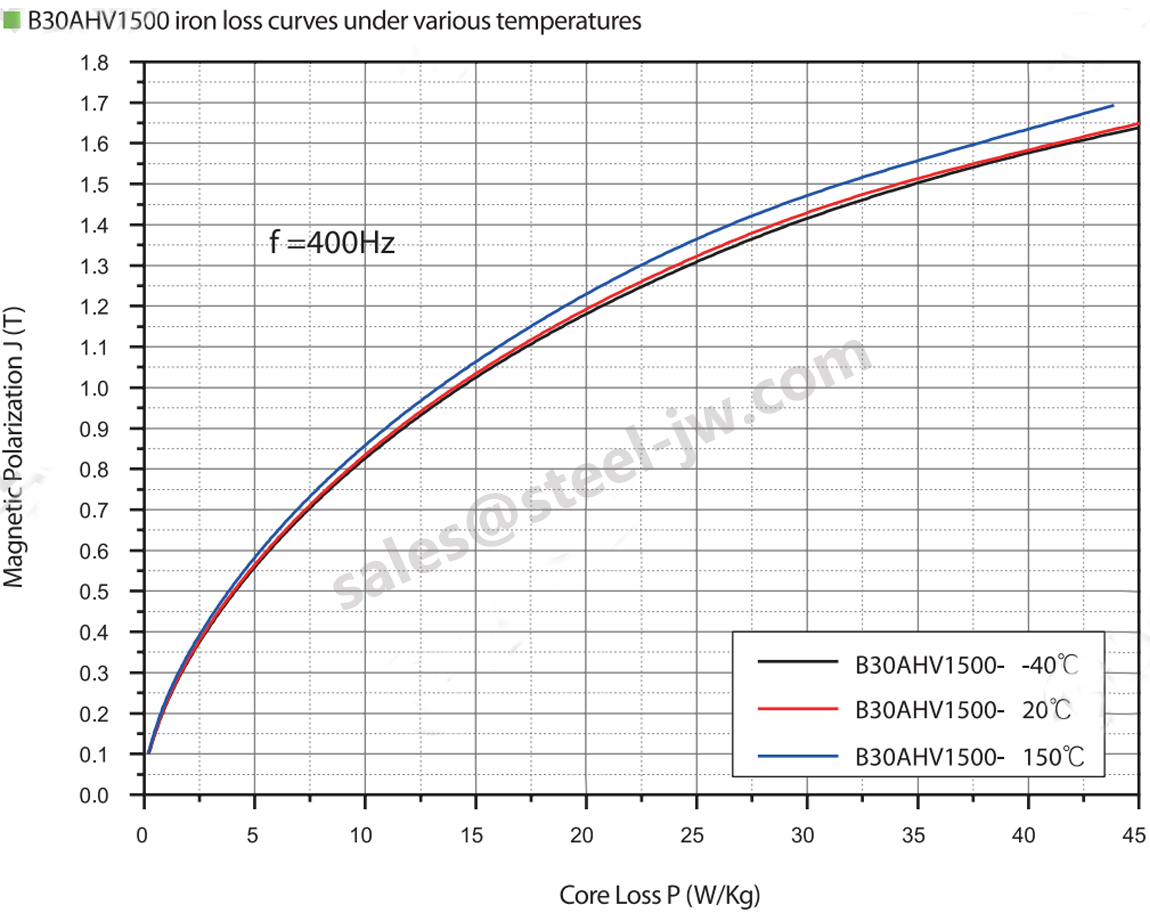

Core loss curves |

Tensile strength |

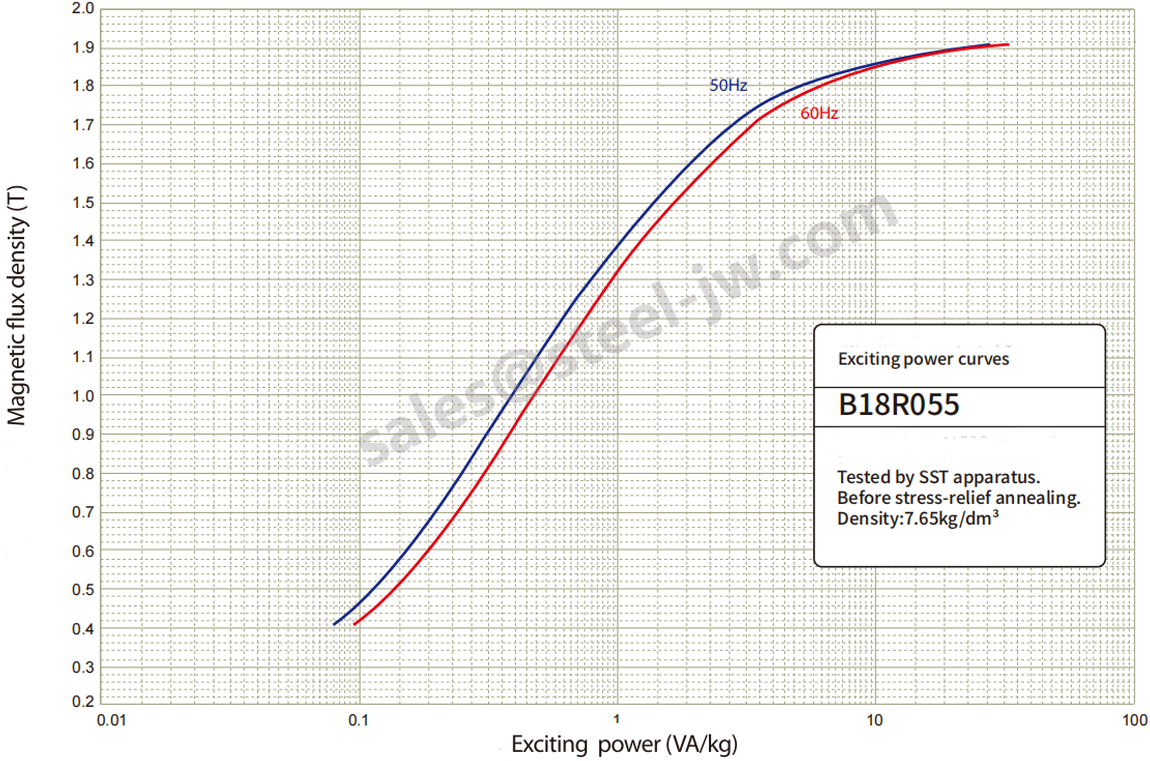

A.C.Exciting power curves |

Number of bends |

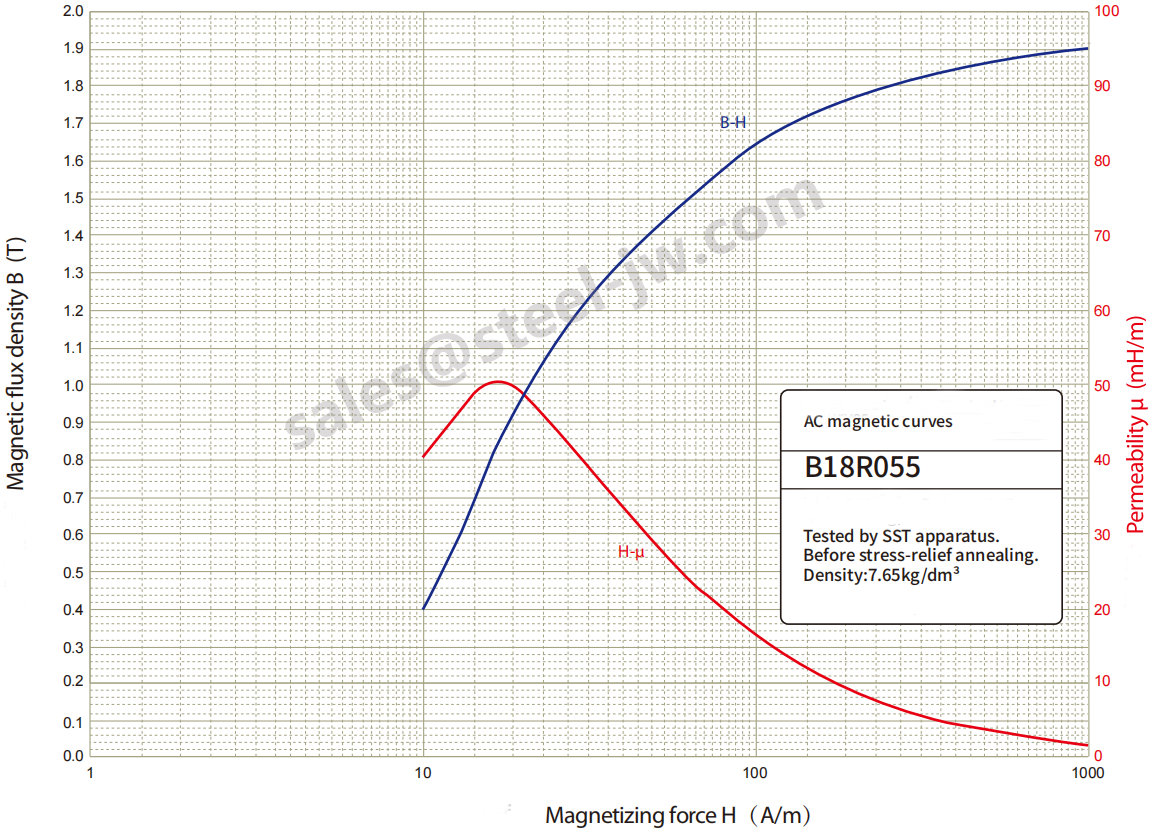

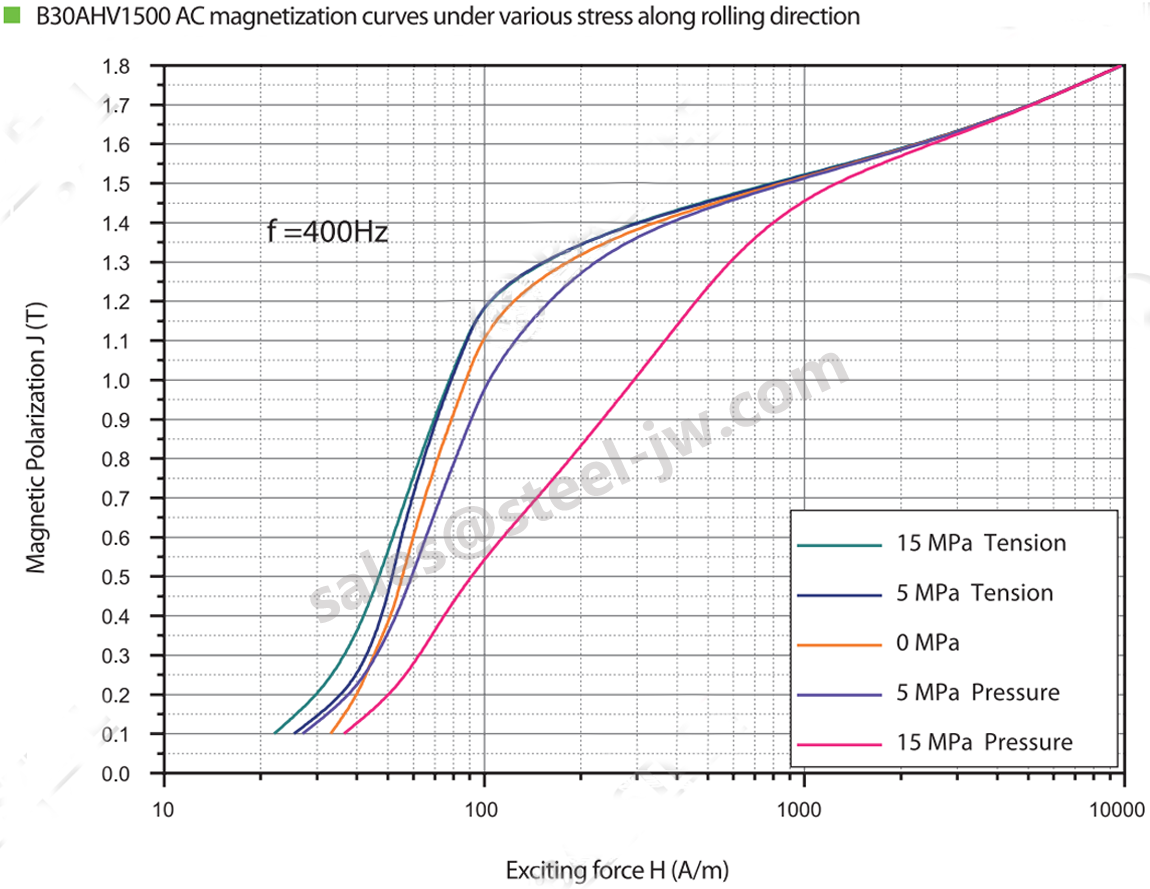

A.C.Exciting curves |

Yield strength |

D.C.Magnetization curves/D.C.Permeability curves |

Elongation |

Core loss at high frqency |

Hardness |

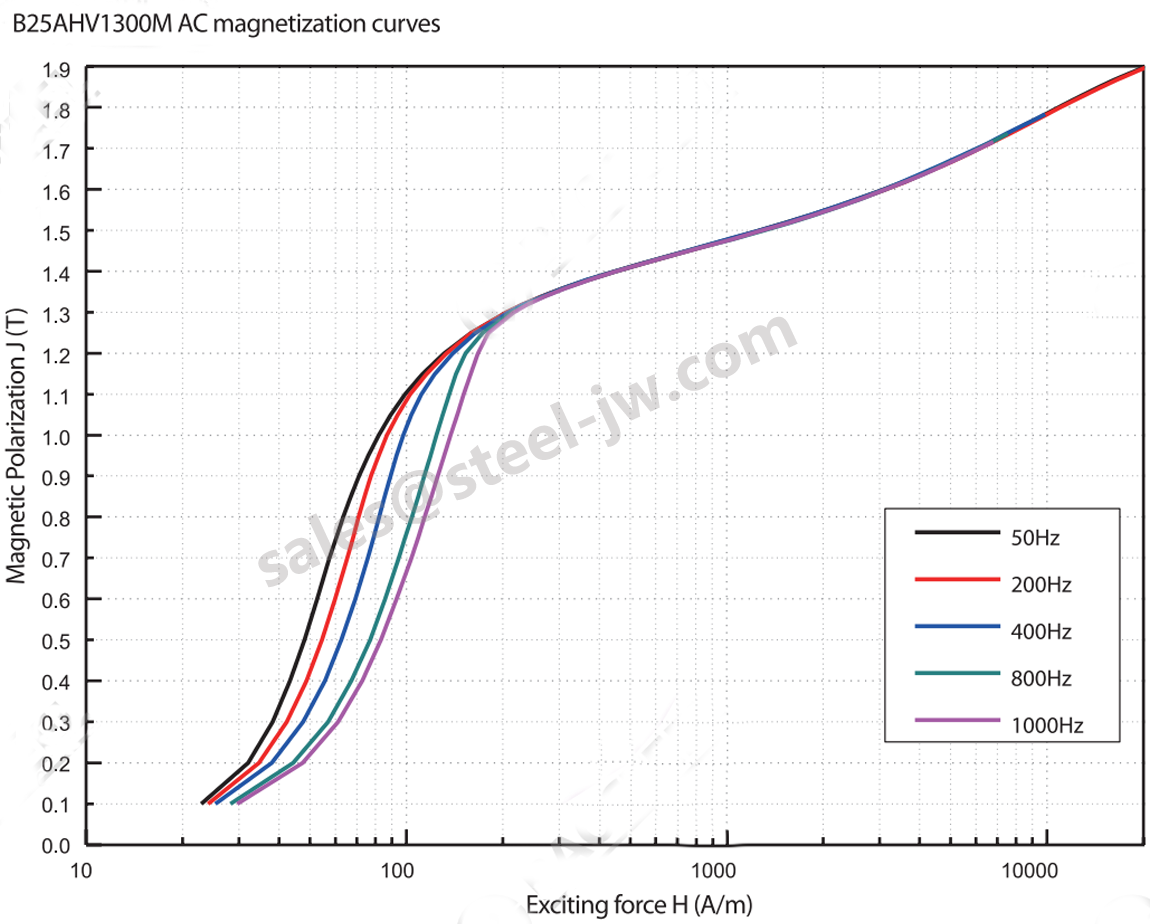

With complete material property test platform, Baosteel couldprovide customers with magnetic property data at any frequency and magnetic flux density of all size of the material,and the measurement of B-P, B-H and H-μ and other forms ofmagnetic property curves, to fully make use of the materialproperties at the greatest extent.

Type |

Grade |

Specific total loss(W/KG)T |

Magnetic polarization(T) |

p(1.5/50) |

|||

High permeability type |

0.74 |

1.89 |

|

0.79 |

1.89 |

||

0.74 |

1.91 |

||

0.79 |

1.89 |

||

0.83 |

1.92 |

||

0.92 |

1.91 |

||

0.94 |

1.91 |

||

0.99 |

1.91 |

||

Domain refined type |

0.54 |

1.91 |

|

0.59 |

1.92 |

||

0.64 |

1.91 |

||

0.59 |

1.92 |

||

0.63 |

1.92 |

||

0.68 |

1.91 |

||

0.69 |

1.90 |

||

0.74 |

1.92 |

||

0.77 |

1.91 |

||

0.80 |

1.91 |

||

0.78 |

1.92 |

||

0.82 |

1.91 |

||

0.86 |

1.90 |

||

B30R080 |

0.88 |

1.92 |

|

0.94 |

1.91 |

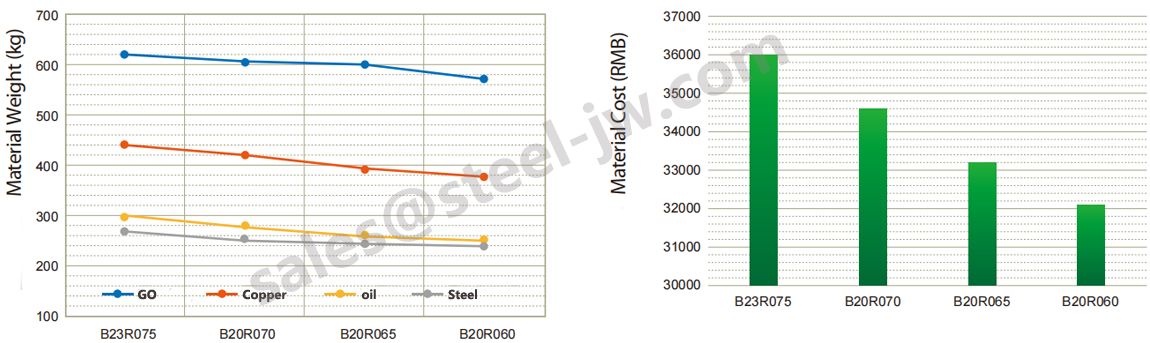

Considering overall the factors such as material properties andprices, Baosteel could supply technical support for materialselection for the design of transformer cores. By effectivecomparison between different materials through predictingcore properties according to the design and process, theoptimal cost can be achieved.

Energy efficiency grades for distribution transformers |

Energy efficiency grade 1 |

Energy efficiency grade 2 |

Oil-immersed distribution transformer |

||

Dry type distribution transformer |

||

B20R060 : typical values P1.7/50=0.59W/kg, B8=1.92T

B18R055: typical values P1.7/50=0.54W/kg, B8=1.91T

High cost-performance ratio is one motivation to use high-performance grain-oriented electrical steel. Taking the new energy efficiency grade 1 laminated core S15-M-400/10-NX1 oil immersed distribution transformer of GB20052-2020 as an example, four kinds of electrical steel grades of Baosteel are used for transformer cost analysis.

GB20052-2020 new energy efficiency grade 1 products S15-M-200/10, S15-M-400/10 transformers have been successfully manufactured with high grade GO electrical steel B18R055, B20R060 , whose no-load loss and load loss all meet the requirements of the new grade 1 transformer.

S15-M-200/10 Test items |

Standard value |

Measured value |

No-load loss,W |

190 |

174(B18R055) |

No-load loss,W |

190 |

181(B20R060) |

S15-M-400/10 Test items |

Standard value |

Measured value |

No-load loss,W |

330 |

282(B18R055) |

No-load loss,W |

330 |

3062(B20R060) |

Grain-oriented electrical steel grades applied |

P1.7/50(W/kg)T |

B8(T) |

0.59 |

1.92 |

|

0.68 |

1.91 |

|

0.69 |

1.92 |

Baosteel adopted two large-scale 110kV main transformer manufactured with B20R070 in the production line to upgrade and reform 2030 cold rolling mill. Arcording to the 30 year life expectancy,14.95 million kWh and 7.475 million RMB cost will be saved.

NO |

Performance indicators |

New main transformer |

Old main transformer |

1 |

No-load loss |

37.46KW |

74.9KW |

2 |

No-load current |

0.06% |

0.31% |

3 |

Load loss |

438.2KW |

522.6KW |

4 |

Energy saving in 30-year life |

14.95million KWh |

-- |

5 |

Cost saving in 30-year life |

7.475million RMB |

-- |

Grain-oriented electrical steel grades applied |

P1.7/50(W/kg)T |

B8(T) |

B23RT075 |

0.72 |

1.91 |

B23RT080 |

0.77 |

1.91 |

B27RT085 |

0.82 |

1.91 |

B27RT090 |

0.86 |

1.91 |

B27RT095 |

0.89 |

1.91 |

B27RT100 |

0.94 |

1.91 |

Baosteel high-grade grain-oriented electrical steel B27R090 wassuccessful applied to manufacturing the dual million transformerODFPS-1000000/1000 for the ultra high voltage Ac transmissionproject. All the transformer properties including no-load lossno-load current and noise meet the design requirements.

Test items |

Guaranteed value |

Measured value |

No-load loss,KW |

185,+15% |

179.9 |

No-load current,% |

0.1 |

0.07 |

Noise,dB(A) |

75 |

72 |

Baosteel high grade grain oriented silicon steel B23R075 has been successfully applied to the production of converter transformer in Changji - Guquan ± 1100kV UHVDC transmission project of State Grid. The no-load loss, no-load current and noise

of the transformer fully meet the technical requirements.

Model |

Grades |

No-load loss |

No-load current |

Noise,dB(A) |

ZZDFPZ-587100/1000-275 |

198.5 |

0.079 |

72 |

|

ZZDFPZ-587100/1000-550 |

199.8 |

0.089 |

73 |

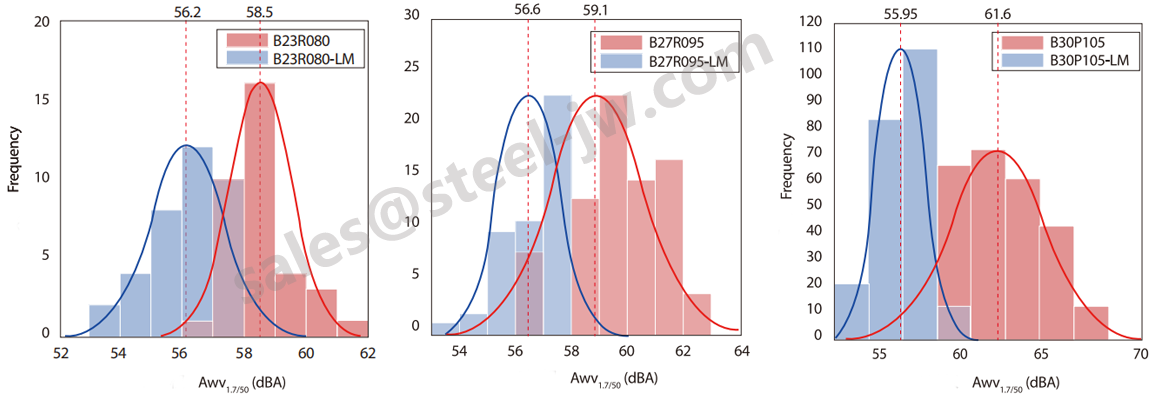

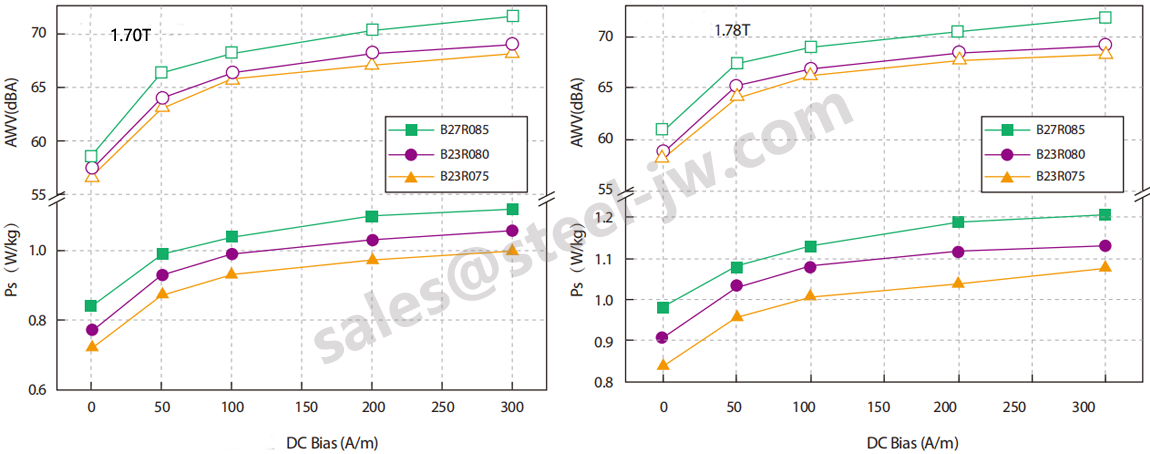

With the development of national economy, densification of population in cities, substation load is increasing. The noise requirements of transformers becomes stricter. Baosteel has also developed low-noise products of 0.23mm, 0.27mm, and 0.30mm.

Grades |

A(wv)1.7/50,dB(A) |

P(1.7/50),W/kg |

B8,T |

|||

Typical value |

Guaranteed value |

Typical value |

Guaranteed value |

Typical value |

Guaranteed value |

|

57 |

≤58 |

0.77 |

≤0.79 |

1.91 |

≥1.88 |

|

57 |

≤58 |

0.80 |

≤0.82 |

1.91 |

≥1.88 |

|

57 |

≤58 |

0.90 |

≤0.94 |

1.91 |

≥1.90 |

|

B30R105-LM |

57 |

≤60 |

1.01 |

≤1.03 |

1.91 |

≥1.90 |

B30R120-LM |

57 |

≤60 |

1.04 |

≤1.06 |

1.91 |

≥1.90 |

Note: Awv,.%, is the A-weighted magnetostriction velocity level at the frequency of 50Hz and the magnetic flux density of 1.7T

With transformer noise 2-3dB(A) lower than the requirement,Baosteel low magnetostriction GO electrical steel has beenwidely accepted by customers.

Power products |

Noise requirements |

Normal material |

Low magnetostriction material B30P105-LM |

SSZ11-240000/220 transformer |

≤63dB(A) |

-- |

60dB(A) |

SB11-M-500/10 transformer |

≤47dB(A) |

44.3dB(A) |

42dB(A) |

SFSZ-180000/220 transformer |

≤63dB(A) |

60dB(A) |

58dB(A) |

SZ-50000/110 transformer |

≤60dB(A) |

58dB(A) |

56dB(A) |

SCB11-10000/10 transformer |

≤50dB(A) |

47.5dB(A) |

44dB(A) |

DF11-120000/750 transformer |

≤65dB(A) |

62dB(A) |

60dB(A) |

S14-M-400/10 transformer |

≤48dB(A) |

45dB(A) |

42dB(A) |

BKS-90000/230 transformer |

≤75dB(A) |

70dB(A) |

69dB(A) |

BKS-75000/238 transformer |

≤75dB(A) |

74dB(A) |

72dB(A) |

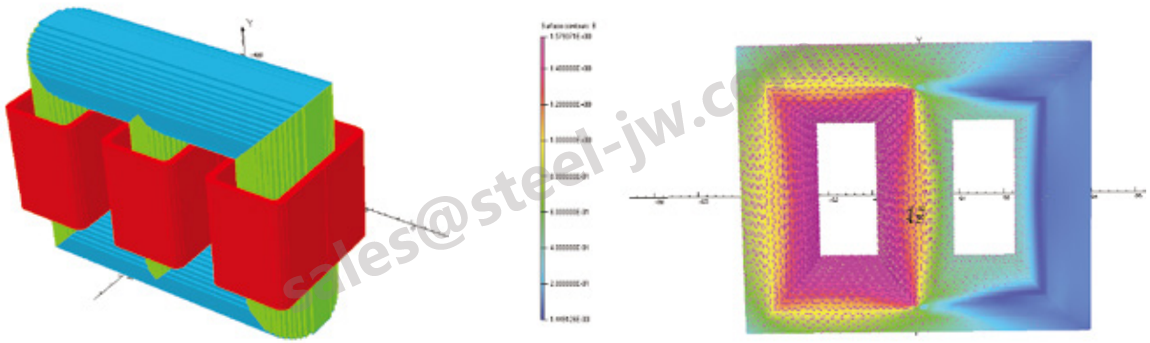

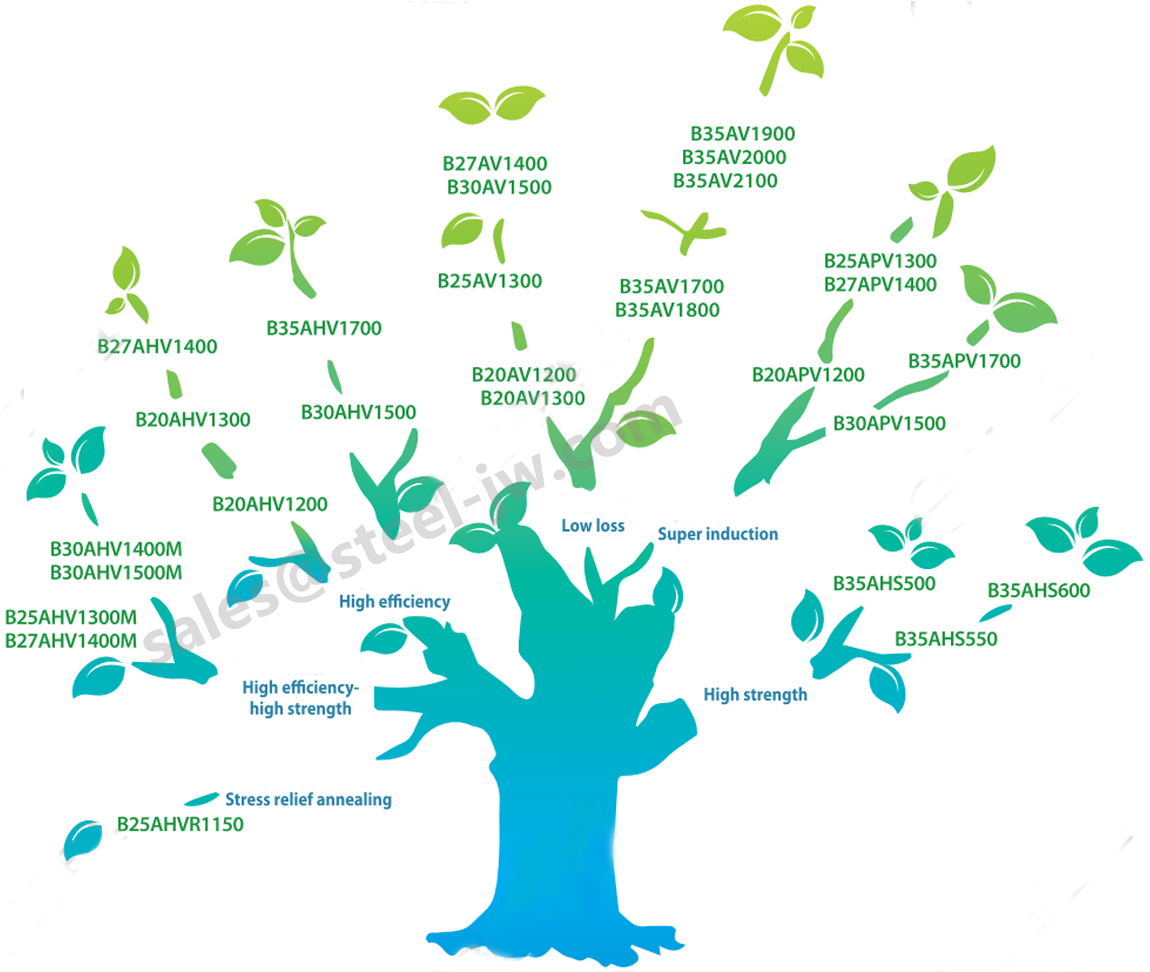

Ability to provide no-load characteristic analysis

Ability to simulate magnetic feld distribution

Ability to simulate DC magnetic bias characteristics

Ability to simulate harmonic characteristics

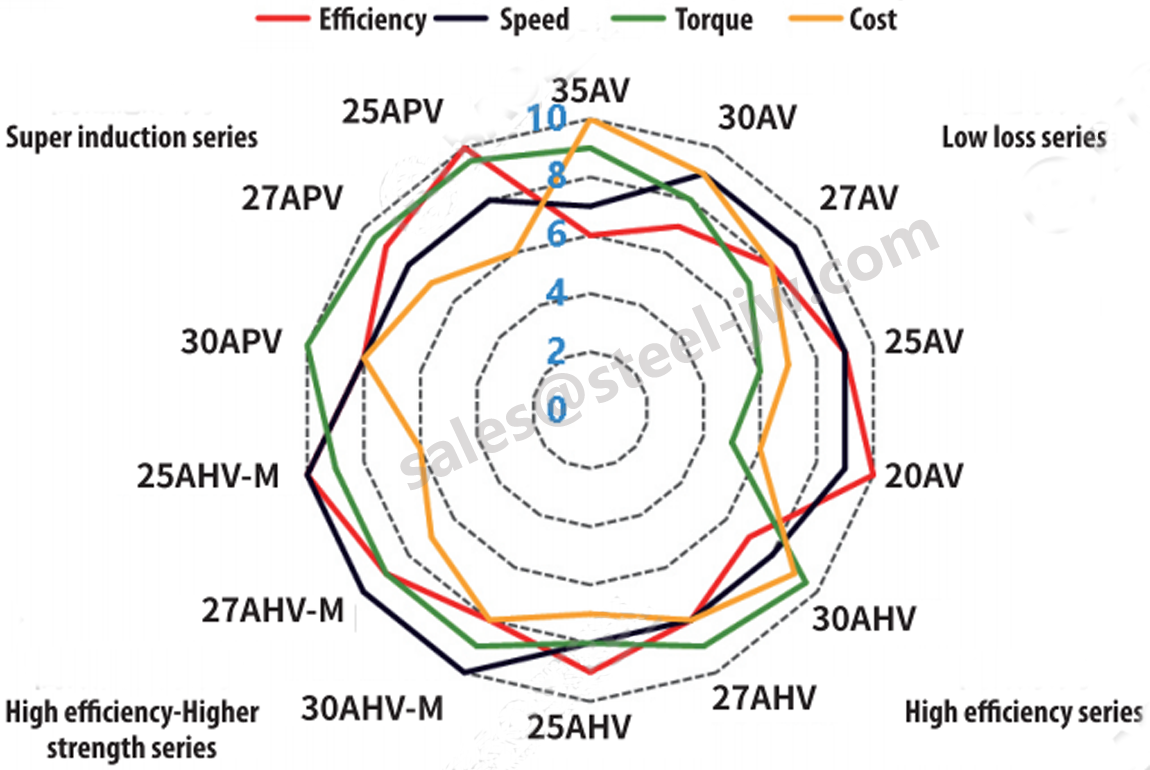

Non-oriented electrical steel series could meet the requirements from all kinds of high performance motors with featuresof low iron loss at mid and high frequency, high induction density and high strength.

1. Low loss series: low iron loss, high strength;

2. High effciency series: low iron loss, high induction;

3. High effciency-Higher strength series: excellent overall performance in loss, induction, and strength;

4. Super induction series: high induction density to satisfy the needs for high torque and compact design of motors;

5. High strength series: high strength for high speed rotor of high speed motors;

6. Stress relief annealing series: low iron loss and high induction after stress reliefannealing.

With complete material properties test platform, Baosteel couldprovide customers with magnetic properties data at any frequency between 20Hz and 10kHz and magnetic flux densityup to 100kA/m, the measurement of B-P, B-H and B-μ and otherforms of magnetic properties curves, to fully make use of the material properties to the greatest extent.

Type |

Grade |

Density(g/cm3) |

P1.0/400(Core loss W/KG) |

P1.0/800(Core loss W/KG) |

Magnetic pplarization(T) |

Yield strength(MPa) |

||

Guarantee value |

Typical value |

Typical value |

Guarantee value |

Typical value |

Typical value |

|||

Low loss AV series |

B20AV1200 |

7.60 |

≤12 |

10.6 |

28.7 |

≥1.61 |

1.63 |

425 |

B20AV1300 |

7.65 |

≤13 |

12.0 |

31.5 |

≥1.63 |

1.64 |

395 |

|

B25AV1300 |

7.60 |

≤13 |

12.0 |

33.2 |

≥1.62 |

1.63 |

430 |

|

B27AV1400 |

7.60 |

≤14 |

13.2 |

37.5 |

≥1.62 |

1.64 |

429 |

|

B30AV1500 |

7.60 |

≤15 |

14.2 |

41.0 |

≥1.63 |

1.64 |

435 |

|

B35AV1700 |

7.60 |

≤17 |

16.2 |

47.5 |

≥1.64 |

1.66 |

438 |

|

B35AV1800 |

7.60 |

≤18 |

17.2 |

50.5 |

≥1.64 |

1.66 |

413 |

|

B35AV1900 |

7.65 |

≤19 |

17.5 |

52.5 |

≥1.65 |

1.67 |

400 |

|

B35AV2000 |

7.65 |

≤20 |

18.5 |

54.8 |

≥1.65 |

1.68 |

380 |

|

B35AV2100 |

7.65 |

≤21 |

19.5 |

57.1 |

≥1.66 |

1.68 |

355 |

|

High efficiency AHV series |

B20AHV1200 |

7.65 |

≤12 |

10.8 |

29.4 |

≥1.64 |

1.65 |

395 |

B20AHV1300 |

7.65 |

≤13 |

12.2 |

32.5 |

≥1.65 |

1.67 |

360 |

|

B27AHV1400 |

7.65 |

≤14 |

13.3 |

38.4 |

≥1.65 |

1.66 |

390 |

|

B30AHV1500 |

7.65 |

≤15 |

14.2 |

40.8 |

≥1.66 |

1.67 |

395 |

|

B35AHV1700 |

7.65 |

≤17 |

16.0 |

47.0 |

≥1.66 |

1.68 |

397 |

|

High induction APV series |

B20APV1200 |

7.65 |

≤12 |

10.6 |

28.9 |

≥1.68 |

1.69 |

395 |

B25APV1300 |

7.65 |

≤13 |

12.2 |

33.8 |

≥1.68 |

1.69 |

383 |

|

B27APV1400 |

7.65 |

≤14 |

13.1 |

37.0 |

≥1.68 |

1.69 |

385 |

|

B30APV1500 |

7.65 |

≤15 |

13.8 |

40.8 |

≥1.68 |

1.69 |

390 |

|

B35APV1700 |

7.65 |

≤17 |

15.8 |

45.9 |

≥1.68 |

1.69 |

395 |

|

Type |

Grade |

Density(g/cm3) |

P1.0/400(Core loss W/KG) |

Magnetic polarization(T) |

Yield strength(MPa) |

|||

Guarantee value |

Typical value |

Guarantee value |

Typical value |

Guarantee value |

Typical value |

|||

High efficiency-Higher strength AHV-M series |

B25AVH1300M |

7.60 |

≤13.0 |

12.0 |

≥1.65 |

1.66 |

≥420 |

442 |

B27AVH1400M |

7.60 |

≤14.0 |

13.1 |

≥1.65 |

1.66 |

≥420 |

441 |

|

B30AVH1400M |

7.60 |

≤14.0 |

13.7 |

≥1.65 |

1.67 |

≥420 |

440 |

|

B30AVH1500M |

7.60 |

≤15.0 |

13.7 |

≥1.65 |

1.67 |

≥420 |

440 |

|

High efficiency AHV series |

B35AHS500 |

7.60 |

≤25.0 |

23.0 |

≥1.64 |

1.66 |

≥500 |

532 |

B35AHS550 |

7.60 |

≤32.0 |

30.0 |

≥1.63 |

1.66 |

≥550 |

575 |

|

B35AHS600 |

7.60 |

≤35.0 |

33.0 |

≥1.60 |

1.65 |

≥600 |

636 |

|

High induction APV series |

B25AHVR1150 |

7.60 |

≤11.5 |

11.2 |

≥1.62 |

1.64 |

≥470 |

485 |

Magnetic properties are measured after annealing at 800°C, 2h.

Type |

Grade |

Density(g/cm3) |

P1.5/50(Core loss W/KG) |

J5000,Magnetic polarization(T) |

Yield strength(MPa) |

||

Guarantee value |

Typical value |

Guarantee value |

Typical value |

Guarantee value |

|||

Low loss A/WW series

|

7.60 |

≤2.28 |

2.10 |

≥1.64 |

1.66 |

405 |

|

7.60 |

≤2.45 |

2.25 |

≥1.64 |

1.66 |

409 |

||

7.65 |

≤2.65 |

2.45 |

≥1.64 |

1.67 |

395 |

||

7.65 |

≤2.90 |

2.55 |

≥1.64 |

1.68 |

385 |

||

7.60 |

≤2.48 |

2.37 |

≥1.64 |

1.66 |

428 |

||

7.60 |

≤2.65 |

2.50 |

≥1.64 |

1.67 |

411 |

||

7.65 |

≤2.85 |

2.60 |

≥1.64 |

1.67 |

400 |

||

7.65 |

≤3.00 |

2.70 |

≥1.65 |

1.68 |

395 |

||

7.70 |

≤3.20 |

2.85 |

≥1.65 |

1.68 |

385 |

||

7.60 |

≤3.30 |

3.00 |

≥1.66 |

1.69 |

333 |

||

35WW250 |

7.60 |

≤2.28 |

2.20 |

≥1.64 |

1.67 |

415 |

|

35WW270 |

7.65 |

≤2.45 |

2.33 |

≥1.64 |

1.67 |

415 |

|

35WW300 |

7.60 |

≤2.65 |

2.45 |

≥1.64 |

1.68 |

395 |

|

35WW360 |

7.60 |

≤3.20 |

2.69 |

≥1.65 |

1.69 |

380 |

|

50WW270 |

7.60 |

≤2.48 |

2.45 |

≥1.64 |

1.67 |

420 |

|

50WW290 |

7.65 |

≤2.65 |

2.49 |

≥1.64 |

1.67 |

420 |

|

50WW310 |

7.65 |

≤2.85 |

2.68 |

≥1.64 |

1.69 |

390 |

|

50WW350 |

7.70 |

≤3.00 |

2.70 |

≥1.65 |

1.69 |

390 |

|

50WW400 |

7.70 |

≤3.20 |

2.83 |

≥1.65 |

1.69 |

380 |

|

50WW470 |

7.75 |

≤3.30 |

3.15 |

≥1.70 |

1.72 |

265 |

|

| High efficiency AH/WH series | B50AH350 |

7.70 |

≤3.00 |

2.85 |

≥1.71 |

1.73 |

302 |

B50AH470 |

7.75 |

≤3.50 |

3.20 |

≥1.72 |

1.74 |

244 |

|

50WH470 |

7.70 |

≤3.00 |

2.86 |

≥1.71 |

1.73 |

300 |

|

50WH600 |

7.75 |

≤3.50 |

3.21 |

≥1.72 |

1.73 |

265 |

|

Coating Properties

Coating code |

A/T4 |

H/T4H |

K |

M |

J/C5 |

Z/C3 |

|

Normal(Cr containing) |

Environmental friendly(Cr free) |

||||||

| ASTM Class | C-5 |

C-5 |

C-5 |

C-5 |

C-5 |

C-3 |

|

| Coating type | Semi-organic |

Semi-organic |

Semi-organic |

Semi-organic |

Semi-organic |

Semi-organic |

|

| Coating thickness(um/surface) | 0.2-0.5um |

0.6-1.0um |

0.3-0.7um |

0.7-1.2um |

2-4um |

3-7um |

|

| Insolation resistance(Ωcm2/piece) | ≥1 |

≥3 |

≥1 |

≥3 |

≥20 |

≥25 |

|

| Adhesiveness | 1 |

3 |

1 |

3 |

1 |

1 |

|

| Punching ability (x1000)puching timesuntil 5Oum burr | 1000 |

1500 |

1000 |

|

|

|

|

| Humidity proof ability | Appearance | No change |

No change |

No change |

No change |

No change |

No change |

| Oil-proof ability | Pass |

Pass |

Pass |

Pass |

Pass |

Pass |

|

| Weld ability(cm/min);maximum weld speed bubble<7 | 80-100 |

20-60 |

80-100 |

20-60 |

10-60 |

Not suitable |

|

| Heat proof ability | long time/air | 180°C |

180°C |

180°C |

180°C |

270°C |

150°C |

| short time air | 210°Cx2500hr/ |

210°Cx2500hr/ |

210°Cx2500hr/ |

210°Cx2500hr/ |

300°Cx2500hr/ |

Not suitable |

|

Above are test data under certain condition in laboratory repre.senting typical properties of coating but not guarantee values

Note: inter-lamination resistance (10 head, toal area 6.45cm2)42)STD11,F15mm round sample, clearance 5% of thick-ness, with stamping oil

50°C, 95% humidity,14 days

In mixed liquid(99.5w% METALUB ATF DEXRON(Vl)+0.5Wt% water) at 180°C for 504hr: no bubble,now-inkle, nopeeling off, and quality difference <5% Protective Ar gas; welding current 120A; F 2.4mm Th-Welectrode; welding torch interval 1.5mm;pressure100kg/cm2

DINIEC 60404-12

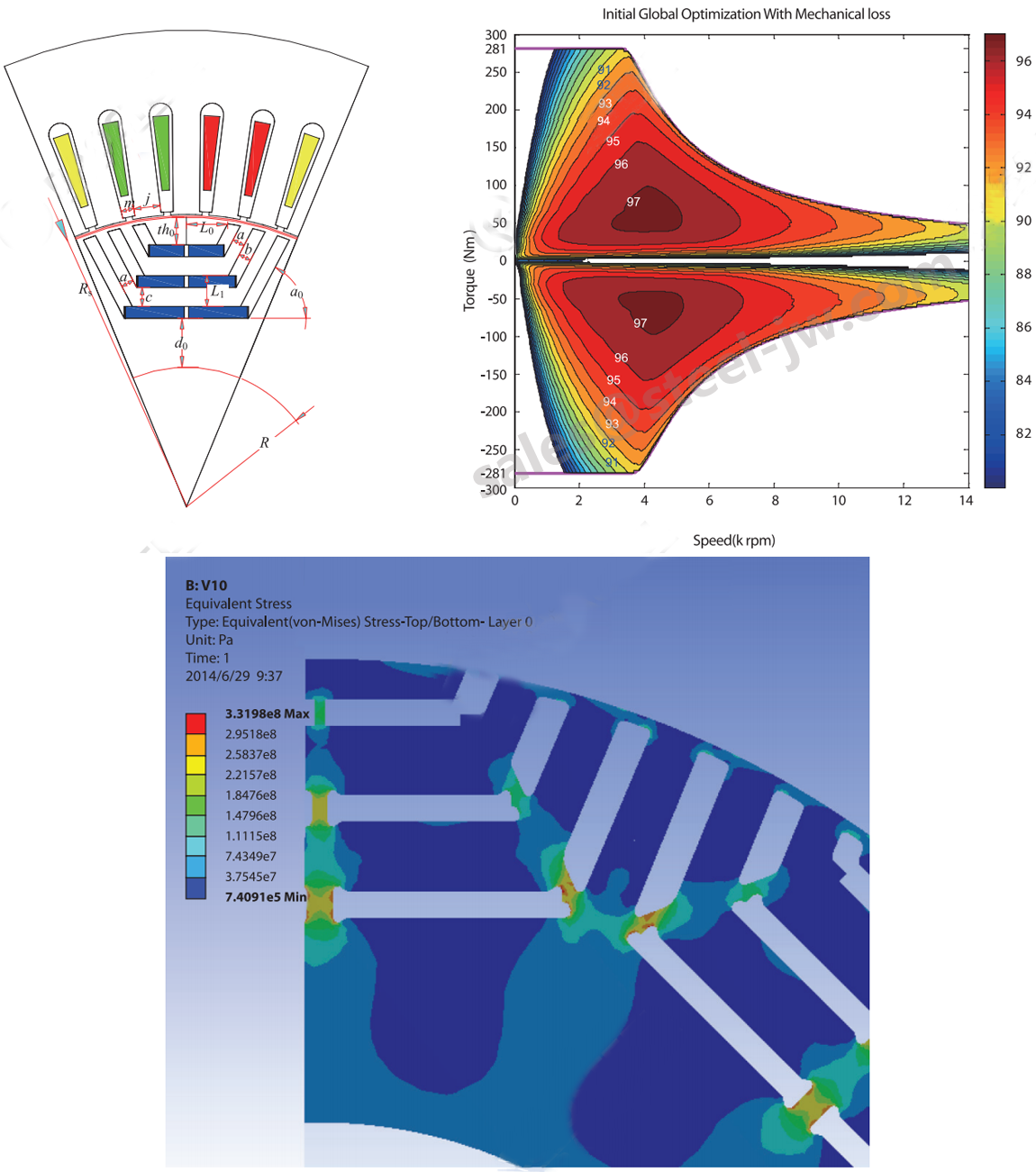

1. Magnetic path analysis for material selection

2. Motor effciency cloud map analysis for material selection;

3. Stress distribution analysis for safety

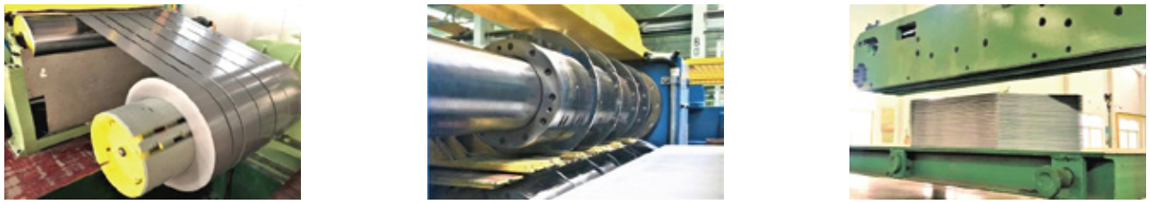

Prototype iron core cutting service: To provide our customerwith electrical steel material, iron core cutting service to avoidprototype punching die building investment in early stage ofnew product development to shorten the R & D cycle.

Properties testing: lron core testing, motor testing.

To support customers for electrical steel selection for design oftraction motor of clean-energy vehicle considering cost and performance, comparison would be done according to core designmanufacturing process design by simulation and experiments torealize an optimized performance price rati0.

Motor Speed And Frequency

It needs to increase motor speed in order to increase motor's pow-er density, the relevant parameters are listed in the following table

Motor speed(rpm-4p) |

Working frequency(Hz) |

9000 |

600 |

10500 |

700 |

12000 |

800 |

15000,18000/21000 |

1000 |

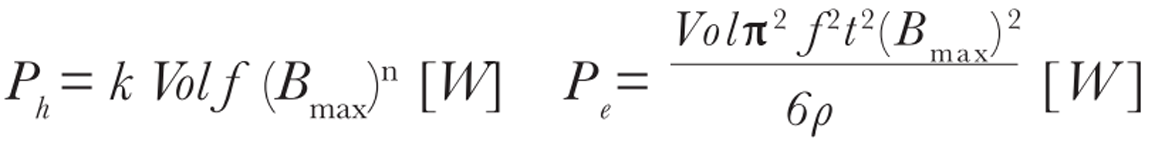

Loss of electrical steel is closely related to frequency(f), wherehysteresis loss Ph is proportional to frequency f, while eddy current loss Pe is proportional to frequency f square ( shown as fol-lowing equation):

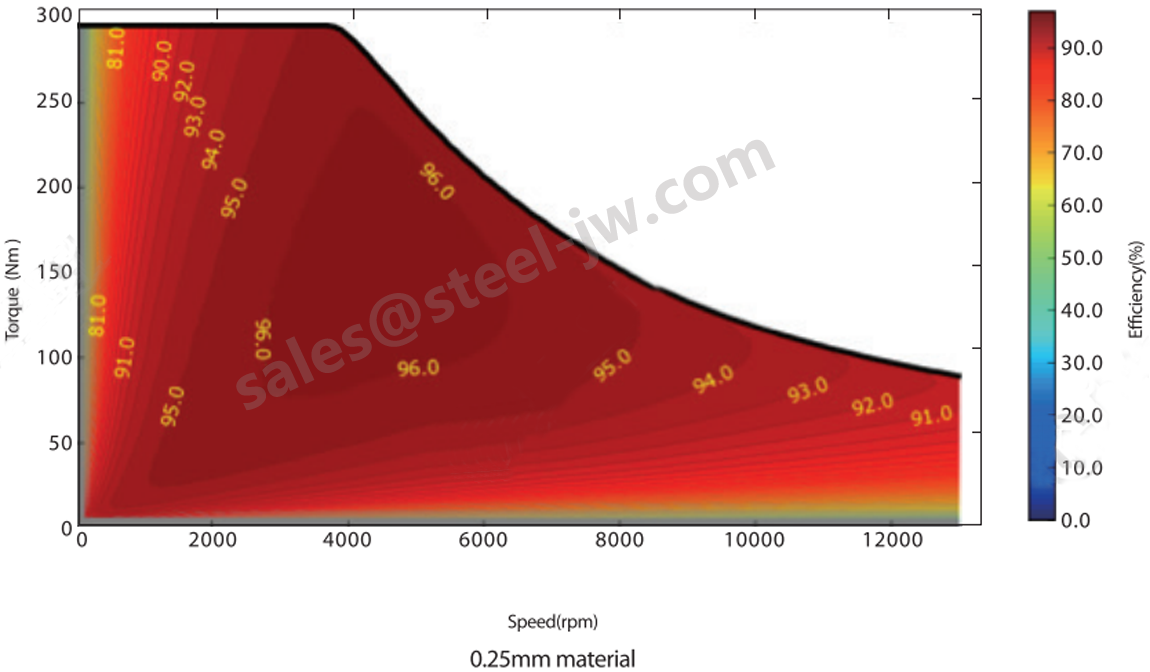

In order to increase motor effciency, it's necessary to decreaseiron loss of electrical steel greatly. The effective way is to reducethe thickness of electrical steel sheet. The iron losses of variousthicknesses at magneticinduction density 1.0T under various fre.quencies are shown in following fqure:

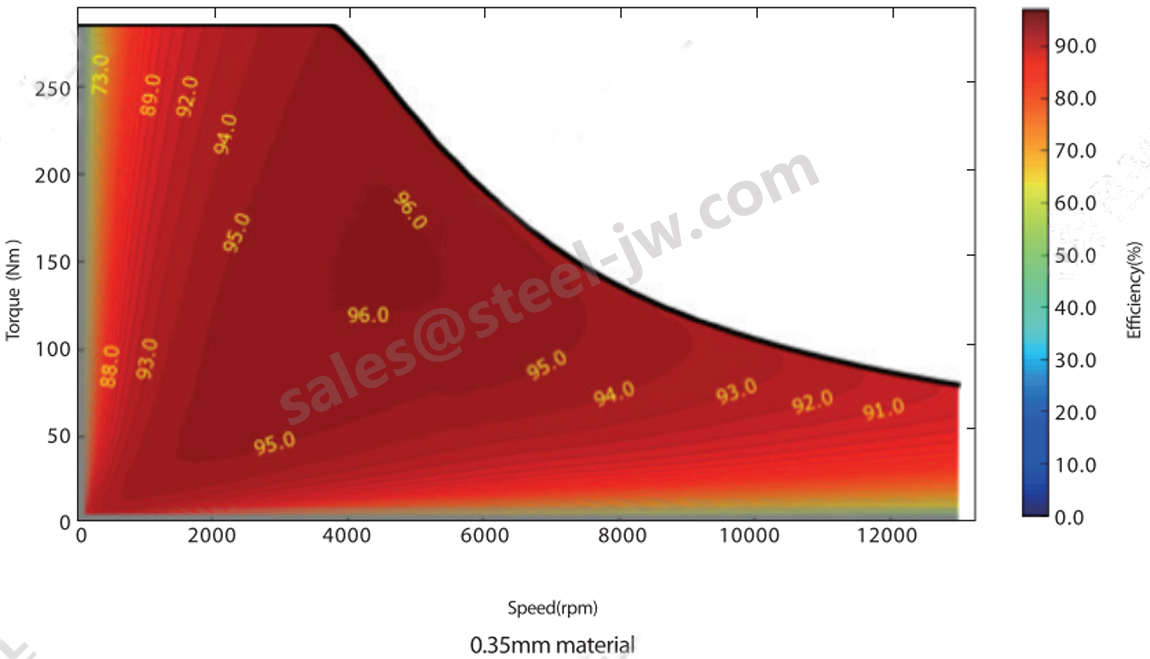

Simulation has been done with various thickness grades, the eff.ciency maps indicated that high effciency area of 0.25mm material is much better than 0.35mm material's.

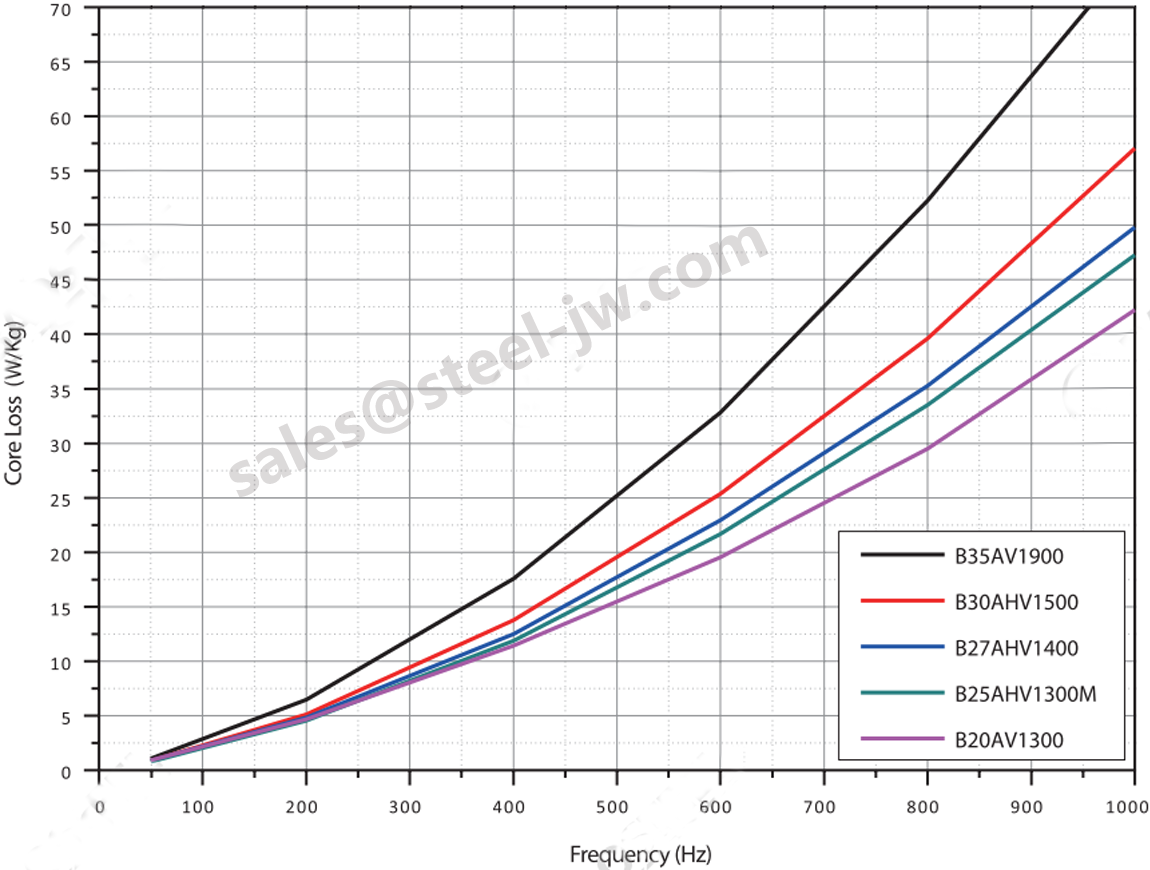

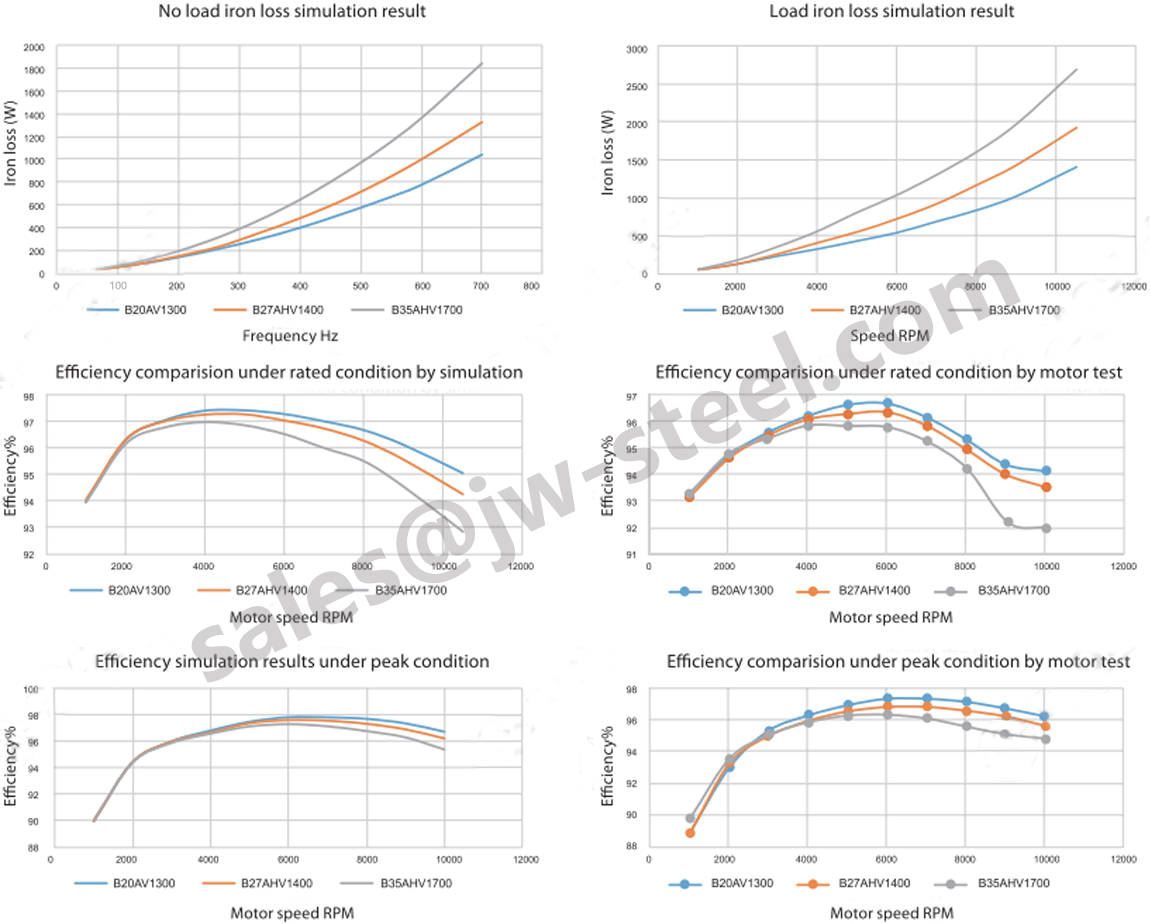

In order to verify the effect of thickness of electrical steel, a designmodel has been used to do simulation analysis and experimentaltesting.lron loss calculation results are shown in following fgures.

The thickness and grade of electrical steel should be determinedby maximum speed (frequency), rated speed(frequency), high efhciency region,and other factor regarding motor performanceand cost. Thin gauge non-oriented electrical steels are good inreducing load loss in high speed region therefore improving mo.tor effciency.

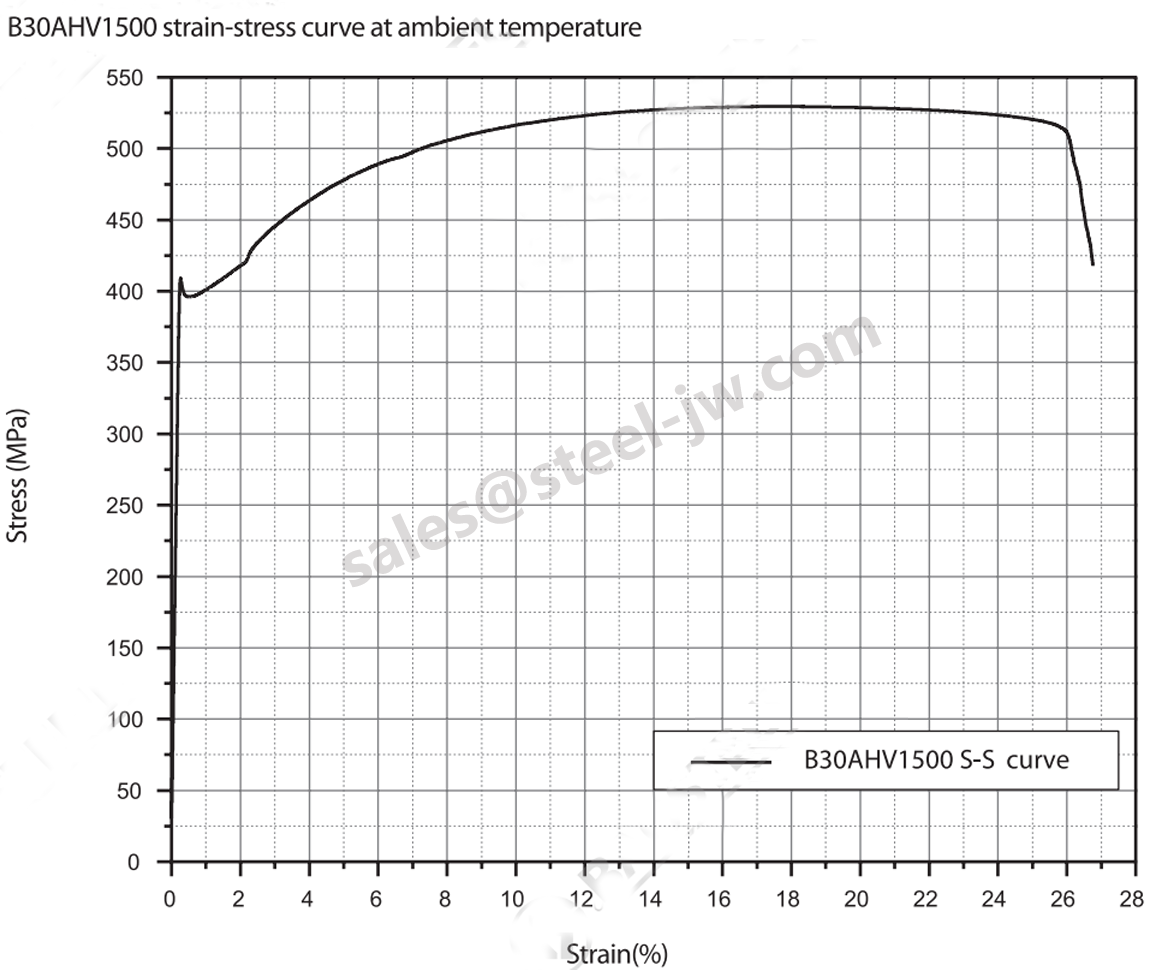

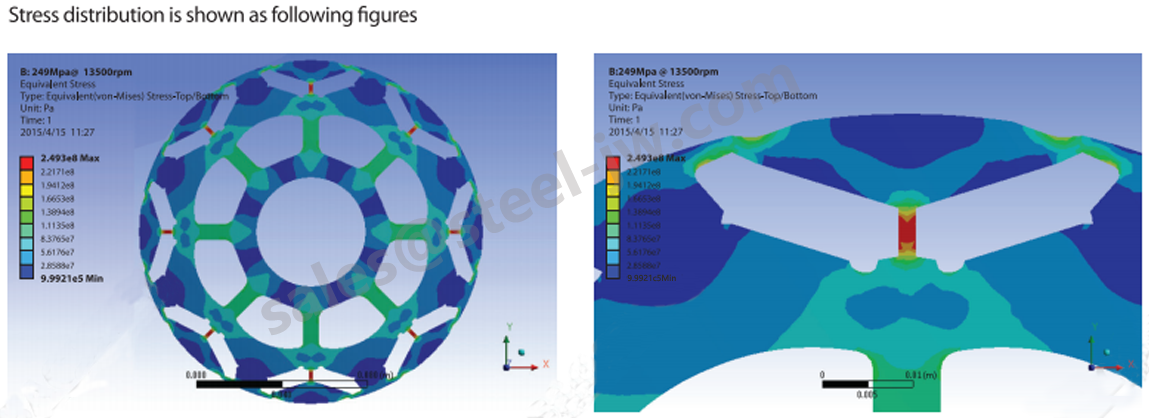

With increasing motor power density, the working frequency andmotor speed are increasing, High strength is needed for electri.cal steel at the magnetic bridge area of rotor because the stressconcentration in this area makes it the weakest point of motorin structure.

Basic data for stress analysis in rotor is shown in the following table: (yield strength of electrical steel is taken as 403MPa)

Motor design |

Equivalent stress |

Safety coefficient |

||

Tmax(Nm) |

Magnetic bridge |

Width(mm) |

||

250.9 |

One place |

1.87 |

249 |

1.62 |

Safety coefhcient 1.62 is the safety factor considering all uncer-tain factors, which includes but not be limited to: actual sizechange of magnetic bridge, variation of material strength, effectof temperature,manufacture resulted stress, speed excess, assembly tolerance, one side magnetic pulling force, etc.

Stress in rotor mainly composes of following parts:

1. Centrifugal force of outer circle (i.e. surrounding bridges) and steelmagnet, being proportional to speed square.

2. Magnetic force between rotor and stator when motor is running, passing on to iron core mainly at bridge, being roughly in inverse proportionto speed above rated speed range.

3. One side pulling force due to uneven magnetic feld, assembly gap, etcbeing a fxed value basically and irrelevant to speed.

Stress in magnetic bridge composes mainly of above three parts, being gen-erally proportional to speed by power between1 to 2, where taking power 1.8.

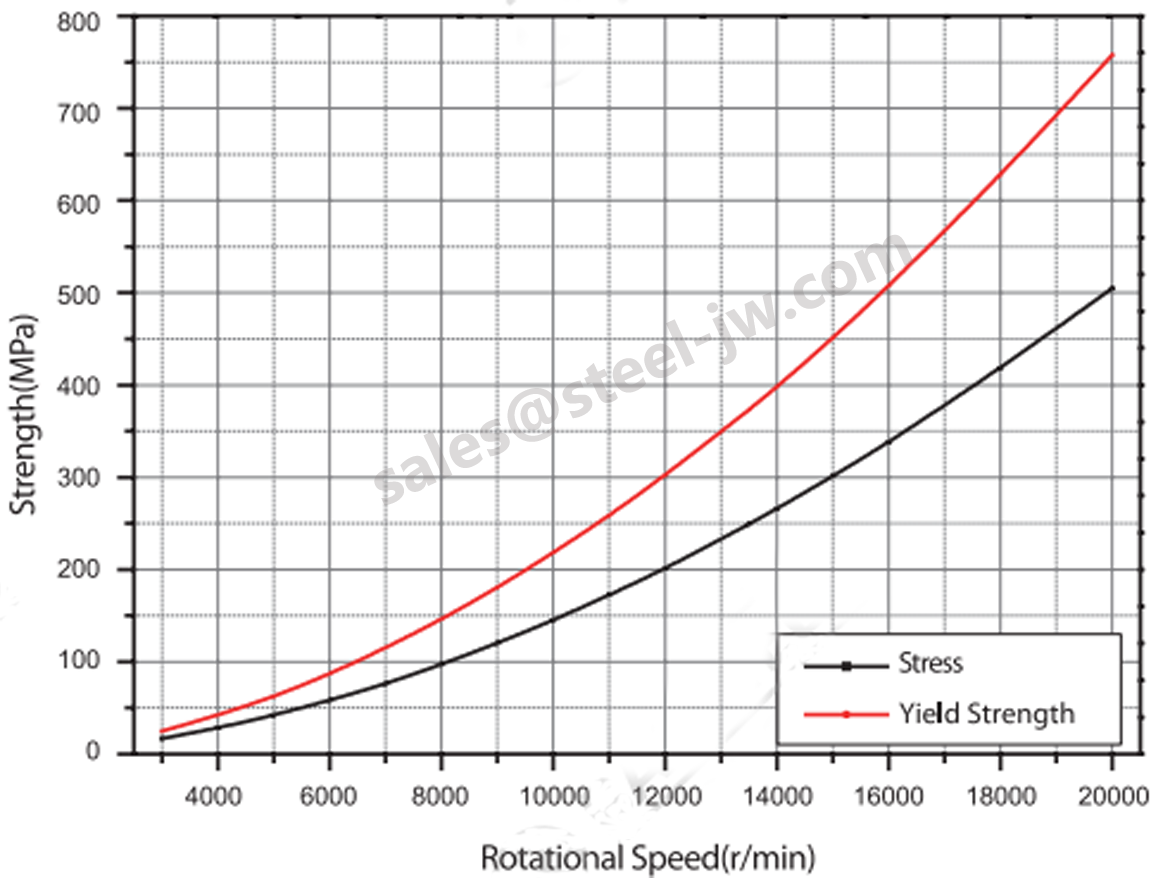

It can been seen that normal electrical steel grades( yieldstrength around 400MPa) could be used without any problemwhen motor speed is lower than 12krpm, but electrical steel withhigher strength (yield strength above 450MPa) are necessarywhen motor speed reaches 15krpm.

Other measures should be taken if strength requirement exceedsthe strenath limit of electrical steel.

Type |

Max revolution ,rpm |

Recommended electrical steel grades |

Passenger cars |

≤10500 |

B30AV1500/B30AHV1500、B35AV1700、B35AV1800、B35AV1900 |

12000 |

B27AV1400/B27AHV1400、B30AV1500/B30AHV1500 |

|

13500 |

B25AHV1300M、B25AV1300、B27AHV1300M、B27AV1400/B27AHV1400 |

|

15000 |

B20AV1200、B20AV1300、B25AHV1300M、B25AV1300、B27AHV1300M |

|

>15000 |

stator:B20AV1200/B20AHV1200、B20AV1300/B20AHV1300 |

|

rotor:B35AHS500/B35ASH550/B35ASH600 |

||

CommercialCars |

≤3000 |

B35AV1900、B35AV2000、B35AV2100 |

4000 |

B35AV1800、B35AV1900、B35AV2000 |

|

6000 |

B35AV1700/B35AHV1700、B35AV1800 |

|

8000 |

B30AV1500/B30AHV1500、B35AV1700/B35AHV1700 |

|

>9000 |

B27AV1400/B27AHV1400、B30AV1500/B30AHV1500 |

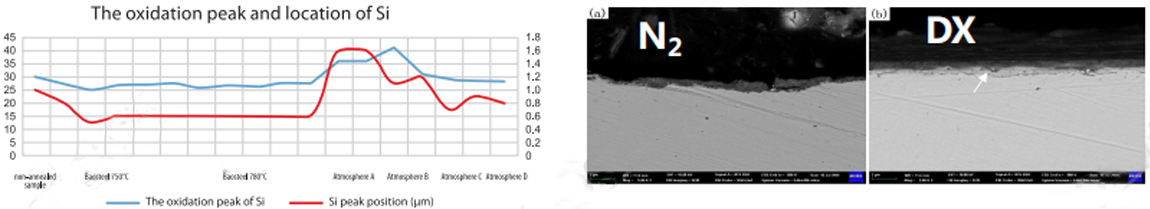

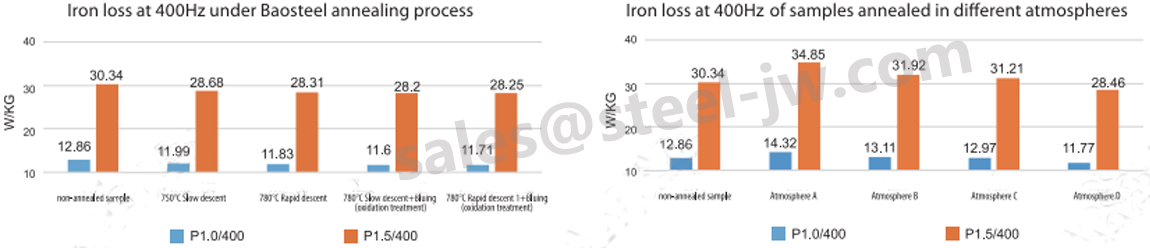

Because of its high silicon content and high temperature in themanufacturing process of steel mill, the performance of the ironcore is closely related to the atmosphere control of the annealingprocess.

As shown in the fgure, the SiO, depth of annealing in N, atmo.sphere is relatively ideal, the SiO, depth of annealing in DX atmosphere A, B and C is 1.6um, and the SiO,depth of annealingin D atmosphere is 0.7um, which indicates the thickness of theoxide flm annealed in DX atmosphere A, B and C, and the oxida.tion depth is consistent with the oxidation strength of the atmo.sphere.

The properties of iron cores prepared from high grade materi.als were tested and compared in different atmospheres after an.nealing.The properties of samples annealed in N,atmosphereare consistent with the variation of process parameters. lt showsthat the iron loss of non-annealed sample is the highest, and theiron loss decreases with the increase of temperature.and the per-formance is the best when the temperature is kept at 780'C Theresults of DX atmosphere annealing process show that the per-formance of iron core after annealing is inconsistent with the ruleof temperature and time, and The iron loss of A/B/C atmospheresamples after annealing is higher than that of the non-annealedsample.

The properties of iron cores prepared from high grade materi.als were tested and compared in different atmospheres after an.nealing.The properties of samples annealed in N,atmosphereare consistent with the variation of process parameters. lt showsthat the iron loss of non-annealed sample is the highest, and theiron loss decreases with the increase of temperature.and the per-formance is the best when the temperature is kept at 780'C Theresults of DX atmosphere annealing process show that the per-formance of iron core after annealing is inconsistent with the ruleof temperature and time, and The iron loss of A/B/C atmospheresamples after annealing is higher than that of the non-annealedsample.

Therefore, the recommendation for core annealing of high gradesilicon steel is as follows:

1. Control annealing atmosphere to avoid forming inner oxidelayer.

2. If it is diffcult for the user to change the atmosphere of theannealing, it is suggested that the motor core should not beannealed according to the actual use situation, which can sta-bilize the performance and save the annealing cost.

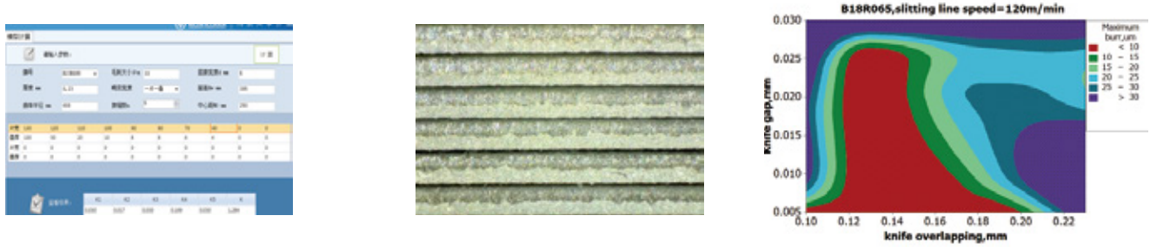

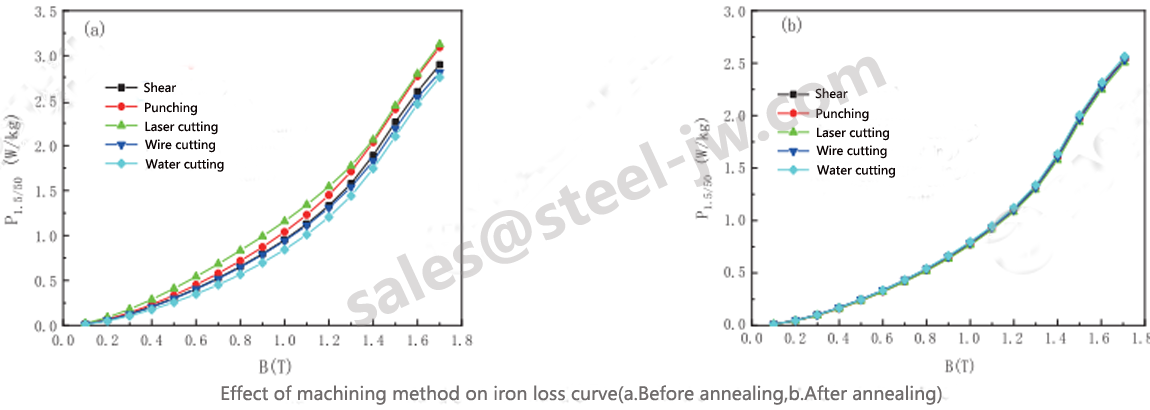

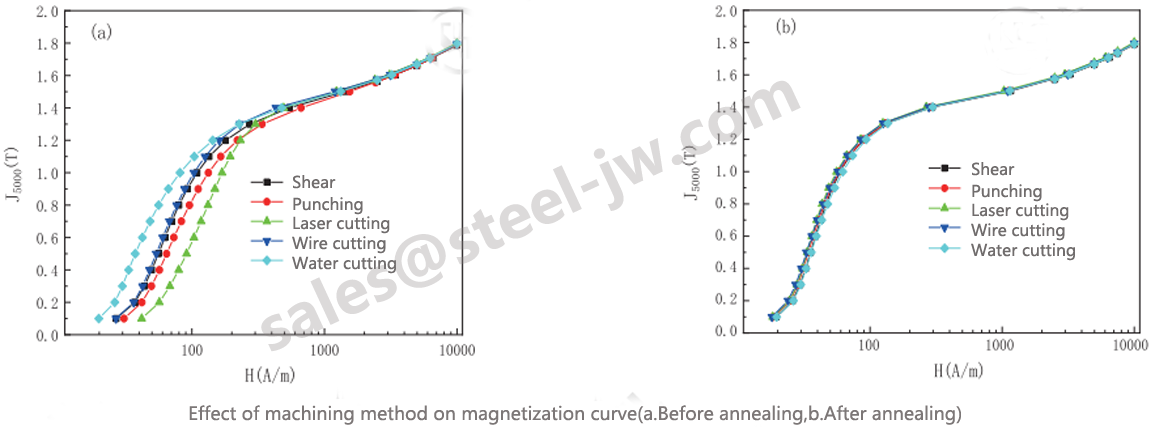

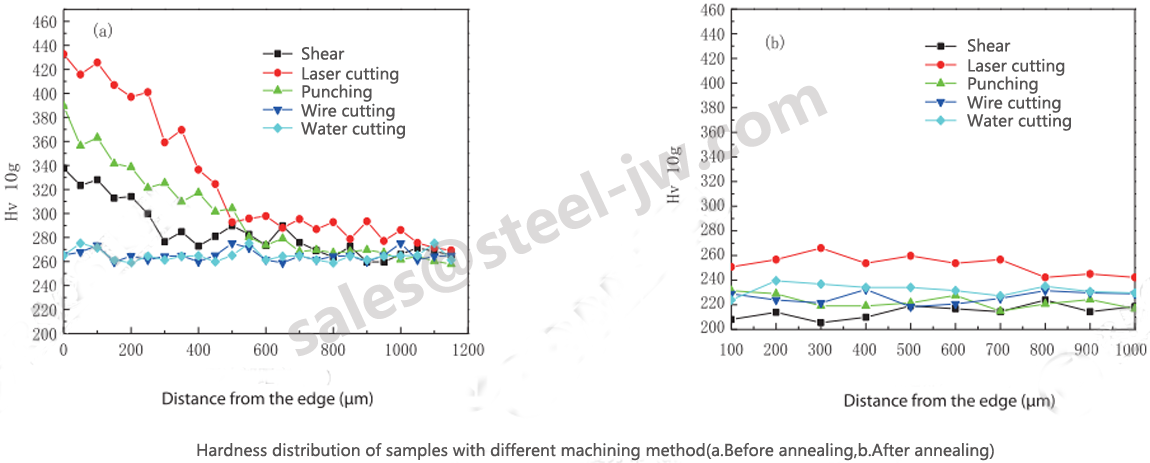

Baosteel high grade non-oriented silicon steel is widely used tomanufacture high energy effciency small and medium motorproducts. However, after the iron core is made by different pro-cessing technology, the performance of the motor is differentTherefore, the effects of continuous punching, laser cutting, wirecutting and water knife cutting on the microstructure and properties of silicon steel are compared.

The laser cut sample has the highest iron loss. The iron loss ofthe punching sample is slightly lower. When the magnetic polar-ization is lower than 1.2T, the iron loss of the sample after shearis similar to that of the sample after wire cutting, but when themagnetic polarization is higher than 1.2T, the iron loss of thesample after shear is slightly greater than that of the samplesafter wire cutting.The iron loss of sample after water cutting isthe lowest.

Before stress reliefannealing, when the external magnetic feld isless than 200A/m, the magnetic polarization of the sample afterlaser cutting is the worst, the punched sample is slightly higher,the magnetic polarization of the sample after wire cutting andshear is comparable, higher than the punched sample, and themagnetic polarization of the sample after water knife cutting isthe highest.

The iron loss of the sample after laser cutting is the highest, be.cause the rapid heating and cooling generated in the laser cut-ting process will produce thermal stress. According to the resultsof hardness distribution, the residual stress at the edge is thelargest, which is very unfavorable to the magnetic properties ofthe sample.lt can be seen from the experimental results that la-ser cutting has the most obvious effect on the deterioration ofiron damage due to the maximum residual stress at the edge.The iron loss of the sample after water cutting is the lowest, be-cause water cutting belongs to cold deformation, neither thermal stress nor plastic deformation of the edge will be generated.After stress relief annealing, the iron loss of each sample tends tobe the same, because after annealing, the edge stress is releasedand the abnormal loss is reduced.

1. Select the appropriate way to process the core in order toachieve the desired goal.

2. In the design of motor energy effciency, it is not only neces-sary to consider the performance of material, but also to adoptreasonable equipment coeffcient in the processing mode ofiron core, so as to approach the design goal as quickly as pos.sible and give a full play to the performance of material.

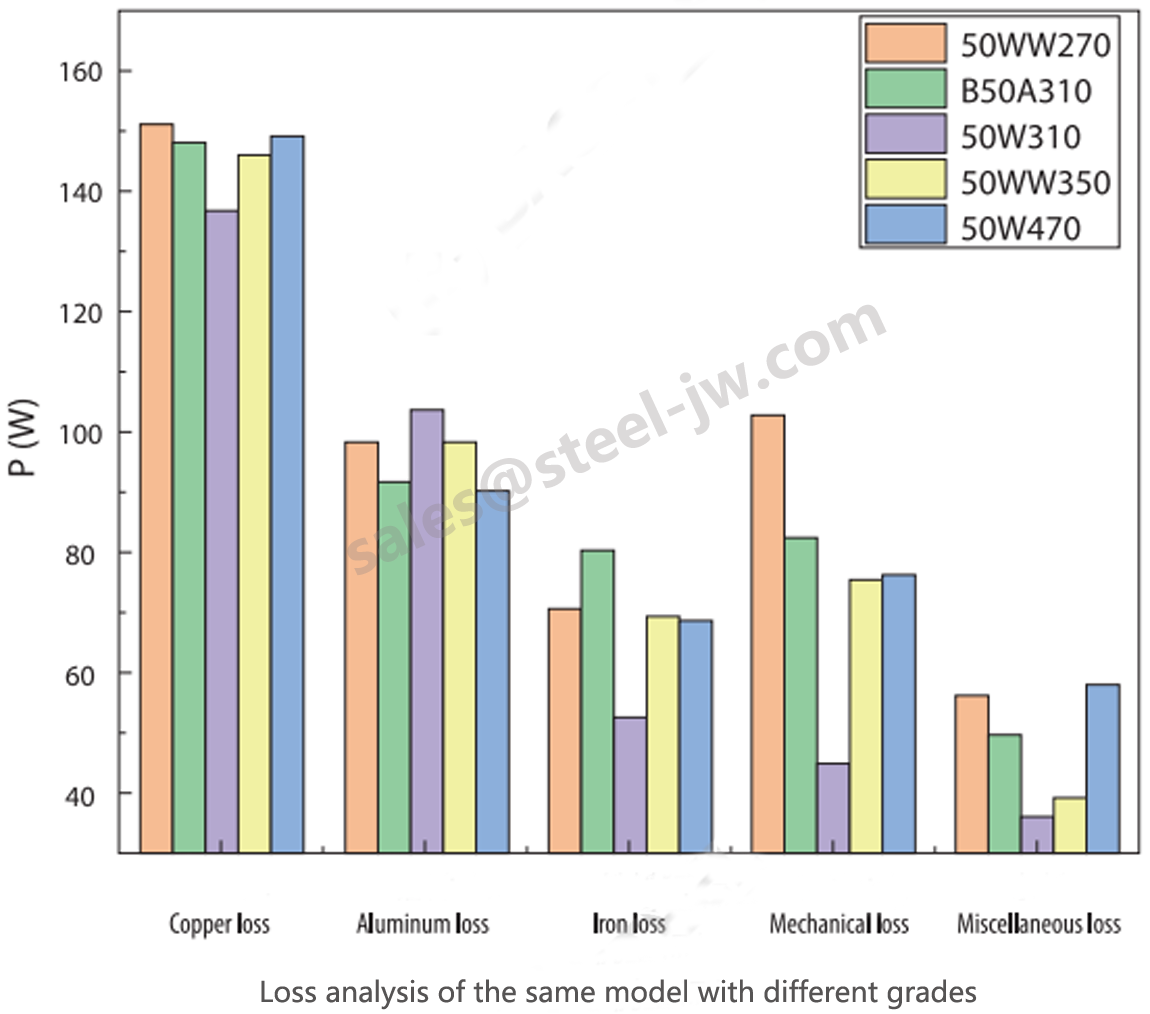

Baosteel's high grade non-oriented silicon steel is widely used tomanufacture high energy effciency industrial motor products.However, with the improvement of the grade of silicon steel, theiron loss distribution shows a decreasing trend, and the maqneticinduction also shows a certain decreasing trend.Therefore, theimprovement of iron core material is not consistent with the re.duction in iron loss.

NO. |

Grade |

P1.5/50(W/kg) |

J5000(T) |

1 |

50WW470 |

3.15 |

1.72 |

2 |

50WH470 |

2.86 |

1.73 |

3 |

50WW350 |

2.70 |

1.69 |

4 |

B50AH300 |

2.70 |

1.70 |

5 |

2.37 |

1.66 |

As can be seen from the fgure above, the loss of the same modelin different grade also show different situations.The high propor-tion of copper loss covers the reduction of core loss caused bythe upgrade of silicon steel grade, so that the overall effciencyimprovement does not match the performance improvement ofsilicon steel raw material, and cannot reach expectations.

The improvement of motor effciency cannot simply apply theoriginal design. lf only the grade of silicon steel raw materialis improved and the loss of iron core is reduced, there shouldalso be changes in groove design and winding design, so as tomake full use of the high grade silicon steel.

In the selection of high grade silicon steel raw materials, whilepaying attention to iron loss, we should also pay attention tothe change ofmagneticinduction, and the proportion of eachtype of motor loss, so as to select or improve raw material toreduce the main loss.